Production deep hole drilling applications are handled with confidence on UNI series machines, built for high accuracy at high volumes, and configurable to build the ideal solution for these demanding applications. UNI machines make the most impact with the least cost by intelligently combining proven components with valuable technologies, developed through our own expertise, and tailored to your drilling needs.

UNI series machines have an impressive range of capabilities, including options for gundrilling, BTA drilling, or a combination, and often integrate automation such as conveyors and robotic technology for optimum production. UNI machines offer generous versatility, and operate as part of an entire system, with tooling, automation, coolant systems, and UNISIG process development and training for long term success.

| Description | UNI-6 | UNI-12 | UNI-20 | UNI-25 | UNI-32 | UNI-50 |

|---|---|---|---|---|---|---|

| Tooling Type | Gundrill | Gundrill | Gundrill | Gundrill | Gundrill | BTA, Gundrill option |

| No. of Spindles | 2,4 | 2,4 | 2,4 | 2,4 | 2,4 | 1 |

| Max drilling diameter | 6 mm | 12 mm | 20 mm | 25 mm | 38 mm | 50 mm |

| Max counterbore diameter | 65 mm | |||||

| Drilling depths | 150 mm

250 mm 500 mm |

500 mm

750mm 1,000 mm |

500 mm

750mm 1,000 mm |

750 mm

1,000 mm 1,500 mm |

1,000 mm

1,500 mm 2,000 mm |

1,000 mm

1,500 mm 2,000 mm 3,000 mm |

| Description | UNI-6 | UNI-12 | UNI-20 | UNI-25 | UNI-32 | UNI-50 |

|---|---|---|---|---|---|---|

| Tooling Type (Option) | Gundrill | Gundrill | Gundrill | Gundrill | Gundrill | BTA, Gundrill option |

| No. of Spindles | 2,4 | 2,4 | 2,4 | 2,4 | 2,4 | 1 |

| Max drilling diameter | 0.25 in | 0.50 in | 0.80 in | 1.00 in | 1.50 in | 2.00 in |

| Max counterbore diameter | 2.50 in | |||||

| Drilling depths | 6.0 in

10.0 in 20.0 in |

20.0 in

30.0 in 40.0 in |

20.0 in

30.0 in 40.0 in |

30.0

40.0 60.0 in |

40.0

60.0 80.0 in |

40.0 in

60.0 in 80.0 in 120.0 in |

UNI Machine Examples

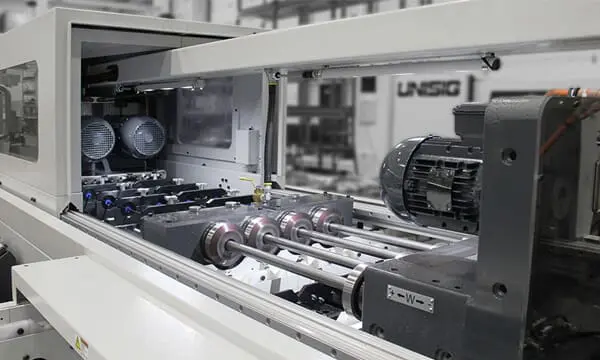

UNI-6-150-4i

This example UNI machine performs high accuracy gundrilling of small parts with multiple off-center and angled holes from 0.7 mm to 6 mm [0.03 – 0.25 in] diameter, up to 150 mm [6.00 in] deep.

Features:

- Integral motor spindles for high speed drilling

- Independent drilling modules for sequential or simultaneous operation

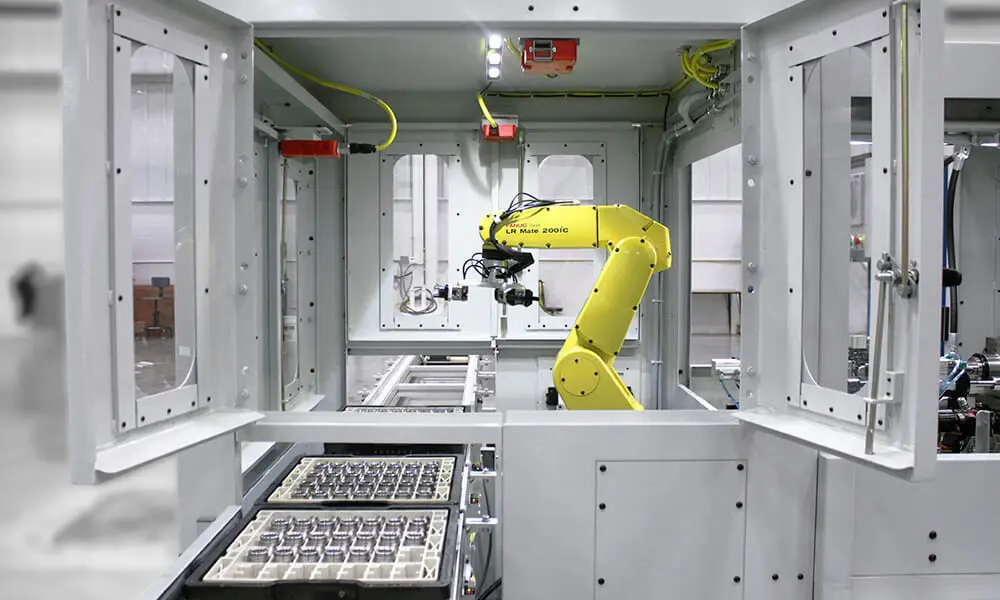

- Tray handling conveyor and robot to automate non-uniform workpiece transfer

- Very high dimensional accuracy of difficult to drill holes

- Exceptional process reliability for critical, small-diameter deep holes

| UNI-6-150-4i Specifications | |

|---|---|

| Number of spindles | 4 |

| Minimum drilling diameter | 0.03 in |

| Maximum drilling diameter | 0.24 in |

| Drill depth shown | 6.0 in |

| Drill depths available | 6.0 in |

| 10.0 in | |

| 20.0 in | |

| Tool spindle power (480v) | 2 hp |

| Tool spindle speed | 20,000 rpm |

| UNI-6-150-4i Specifications | |

|---|---|

| Number of spindles | 4 |

| Minimum drilling diameter | 0.70 mm |

| Maximum drilling diameter | 6.00 mm |

| Drill depth shown | 150 mm |

| Drill depths available | 150 mm |

| 250 mm | |

| 500 mm | |

| Tool spindle power (480v) | 1.5 kw |

| Tool spindle speed | 20,000 rpm |

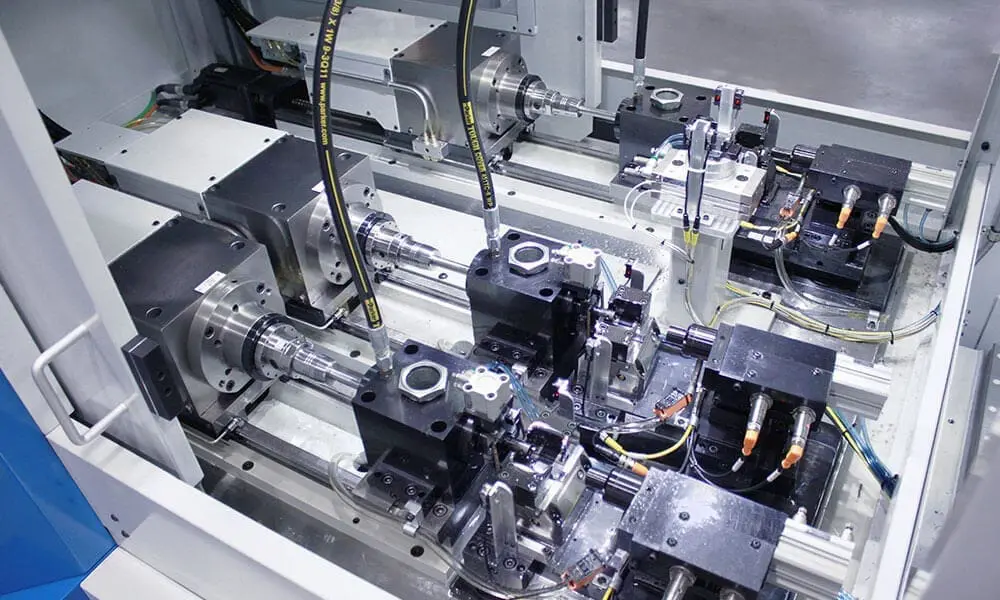

UNI-12-4-750-CR

This example UNI machine performs high volume production gundrilling of shafts with very straight holes from 3 to 12 mm [0.12 to 0.50 in] diameter, up to 750 mm [30.0 in] deep.

Features:

- Counter-rotation for minimized centerline drift and high concentricity

- Programmable workpiece headstock position and clamping force

- Automatic loading system, adjustable for workpiece length and diameter

- Compact construction for installation in a CNC machining cell or larger integrated drilling system

| UNI-12-4-750-CR Specifications | |

|---|---|

| Number of spindles | 4 |

| Minimum drilling diameter | 0.12 in |

| Maximum drilling diameter | 0.50 in |

| Drill depth shown | 30.0 in |

| Drill depths available | 20.0 in |

| 30.0 in | |

| 40.0 in | |

| Tool spindle power (480v) | 3 hp |

| Tool spindle speed | 12,000 rpm |

| Work spindle power (480v) | 1 hp |

| Work spindle speed | 2,000 rpm |

| UNI-12-4-750-CR Specifications | |

|---|---|

| Number of spindles | 4 |

| Minimum drilling diameter | 3.00 mm |

| Maximum drilling diameter | 12.0 mm |

| Drill depth shown | 750 mm |

| Drill depths available | 500 mm |

| 750 mm | |

| 1,000 mm | |

| Tool spindle power (480v) | 2.2 kw |

| Tool spindle speed | 12,000 rpm |

| Work spindle power (480v) | 0.8 kw |

| Work spindle speed | 2,000 rpm |

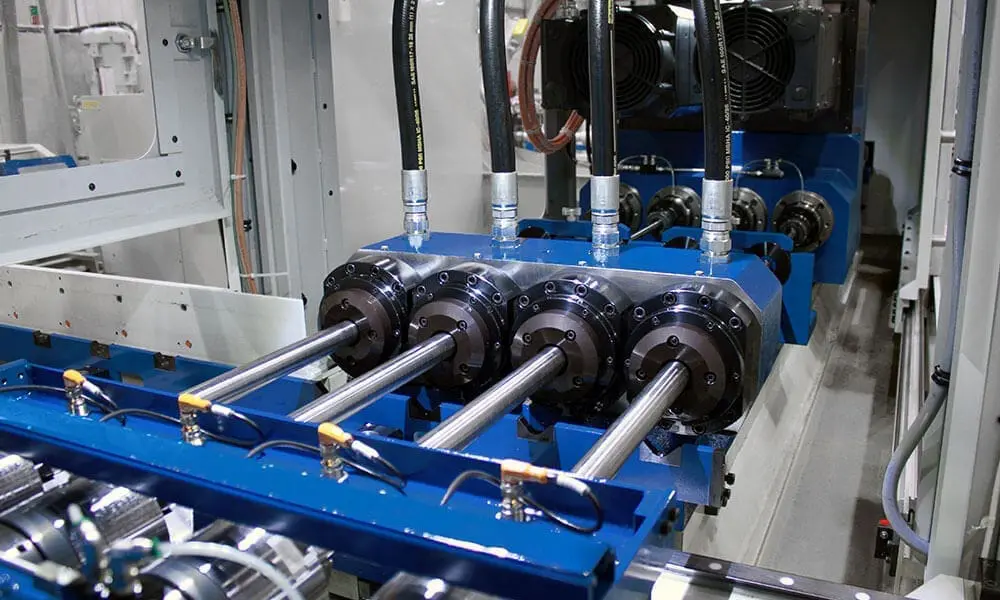

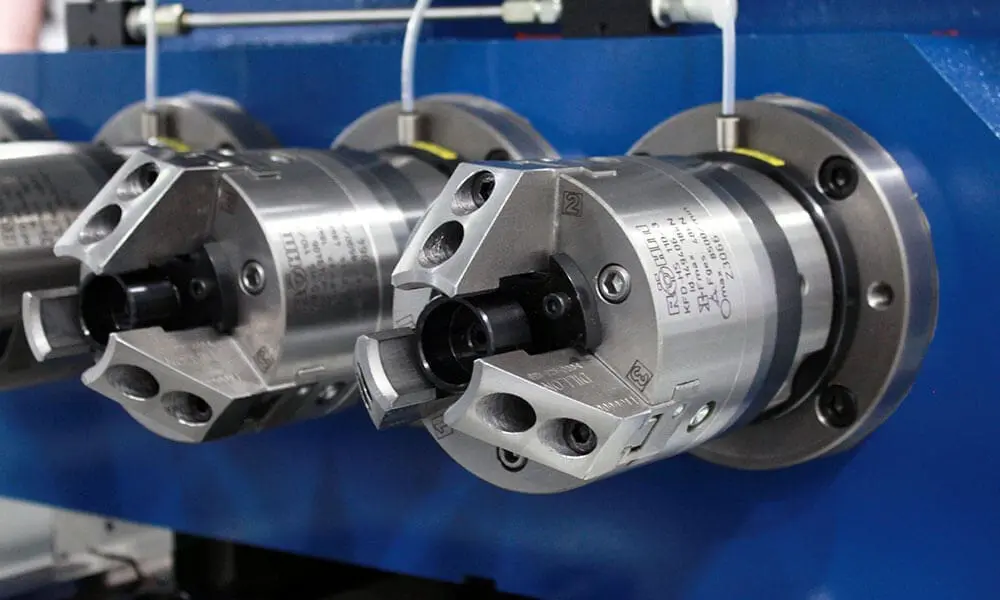

UNI-25BTA-4-750-CR

This example UNI machine is a high power four-spindle machine for production BTA drilling of holes from 12 mm to 25 mm [0.47 to 1.00 in] diameter, up to 750 mm [30.0 in] deep.

Features:

- Ultra-high feed rates using BTA tooling

- Hydraulic clamping chucks for increased driving torque with high performance tools

- Servo driven loader for automatic workpiece diameter adjustment

- Cell integrated, robot ready design

| UNI-25BTA-4-750-CR Specifications | |

|---|---|

| Number of spindles | 4 |

| Minimum drilling diameter | 0.47 in |

| Maximum drilling diameter | 1.00 in |

| Drill depth shown | 30.0 in |

| Drill depths available | 30.0 in |

| 40.0 in | |

| 60.0 in | |

| Tool spindle power (480v) | 19 hp |

| Tool spindle speed | 3,000 rpm |

| Work spindle power (480v) | 5 hp |

| Work spindle speed | 500 rpm |

| UNI-25BTA-4-750-CR Specifications | |

|---|---|

| Number of spindles | 4 |

| Minimum drilling diameter | 12.0 mm |

| Maximum drilling diameter | 25.0 mm |

| Drill depth shown | 750 mm |

| Drill depths available | 750 mm |

| 1,000 mm | |

| 1,500 mm | |

| Tool spindle power (480v) | 15 kw |

| Tool spindle speed | 3,000 rpm |

| Work spindle power (480v) | 3.7 kw |

| Work spindle speed | 500 rpm |

Features:

- Rapid changeover from BTA to gundrill tooling

- Counter-rotation for minimized centerline drift

- High precision zero endplay spindles for bottom forcing operations

- Preloaded ballscrew drives for precise depth control

- Process monitoring and graphical display of critical information

- Automatic process interruption for unattended operation

| UNI-50BTA-1500-CR Specifications | |

|---|---|

| Tooling type | Gundrill and BTA |

| Minimum drilling diameter | 0.31 in |

| Maximum drilling diameter | 1.97 in |

| Max counterbore diameter | 2.56 in |

| Drill depth shown | 59.0 in |

| Drill depths available | 40.0 in |

| 60.0 in | |

| 80.0 in | |

| 120.0 in | |

| Tool spindle power (480v) | 38 hp |

| Tool spindle speed | 3,000 rpm |

| Work spindle power (480v) | 27 hp |

| Work spindle speed | 1,000 rpm |

| UNI-25BTA-4-750-CR Specifications | |

|---|---|

| Tooling type | Gundrill and BTA |

| Minimum drilling diameter | 8.00 mm |

| Maximum drilling diameter | 50.0 mm |

| Max counterbore diameter | 65.0 mm |

| Drilling depth shown | 1,500 mm |

| Drill depths available | 1,000 mm |

| 1,500 mm | |

| 2,000 mm | |

| 3,000 mm | |

| Tool spindle power (480v) | 28 kw |

| Tool spindle speed | 3,000 rpm |

| Work spindle power (480v) | 20 kw |

| Work spindle speed | 1,000 rpm |

UNI Machine Recommendations

Recommended Tooling

- Gundrill Durable Tooling

- BTA Durable Tooling

Recommended Automation

- Robotic Automation

- Robot Ready Automation

- Tray Handling Conveyors

- Pallet Changing

- Servo Driven Gantry

- Programmable Smart Conveyors

- Walking Beam

- Pick and Place

- Magazine Loader

- Bulk Feeder