Core Competency – Mechanical Assembly

A machine is more than the sum of its parts. Our mechanical assembly team builds machines, with a deep knowledge of what the machines will do when completed, and how they will work. Some of our machines sell for several million dollars – nothing on the assembly floor is left to chance.

At UNISIG, there are always a lot of projects moving through build and there is a lot to keep track of. Each step must be exactly right before moving forward. Our machines are complex, but we put them together systematically guided by experienced leaders in our team, and they work.

Mechanical Assembly – How we do it better

Many of our projects are standard machines, so we have a flow in our work that becomes an expectation. We are always on the hunt for improvement. New tools, new techniques and higher standards that will also improve our throughput. There is excitement when a brand-new machine base gets leveled out to start a project: This is going to be the best one yet.

UNISIG is known for driving the industry forward. This means there are new ideas being transformed into reality, and sometimes reality is harsh. Our mechanical assembly teams are normally the first ones to experience the full weight of each project. Our build leaders have been trained to anticipate obstacles and overcome them before they cause issues.

Machine Building

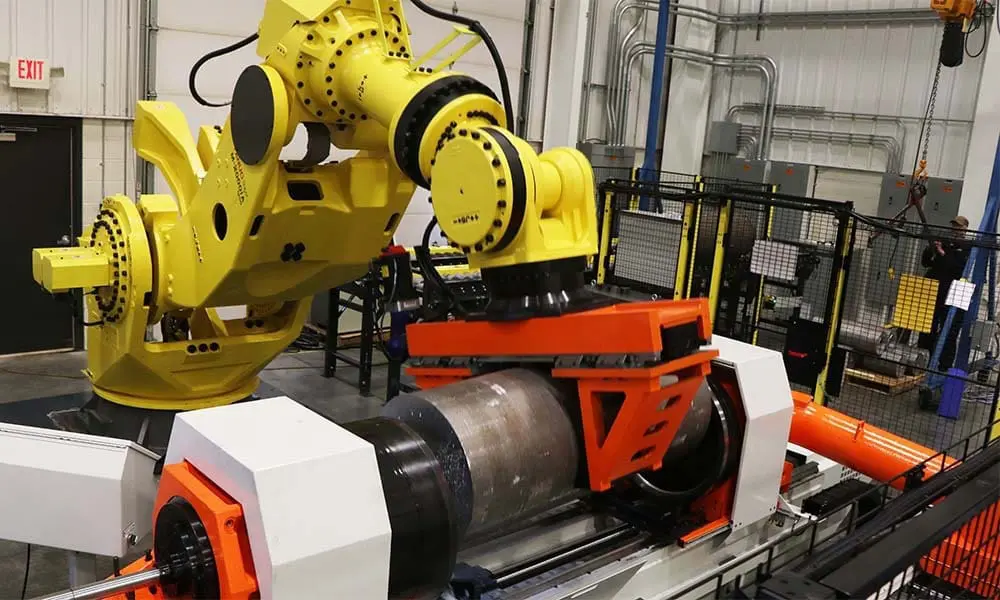

Our machines are impressive. When three of them are put together in a cell with a robotic handling system they are seriously fun to build. We start all these projects with the core mechanical – machine bases, structure, axis drives and headstocks. Alignment of these items during build is what sets up the final geometry checks for success.

After the core is together the next phases that have an enormous impact on reliability and future maintenance needs are started – sheet metal enclosures, plumbing and utility routing, automated motion. Electrical feedback devices and sensors are mounted so they withstand the rigors of a harsh environment.

Precision Subassembly

Precision machine tools have high-speed spindles, geared transmissions, exotic actuated tools and other modules that are best put together away from the other high-activity areas of manufacturing and assembly. UNISIG builds and fully tests these components in our precision sub-assembly area.

Every part must be perfect – inspected, cleaned and lubricated. Critical fits are measured one more time before using liquid nitrogen or induction heaters to assemble without resorting to the hammers other companies use. Every fastener torqued and marked. Our core value “committed to detail and consistency” is critical here.

Fluid Power

Hydraulics, pneumatics, lubrication and cutting fluid systems are part of our mechanical expertise. During the core mechanical build, there is a lot of plans made for plumbing routes and installing fluid power devices. We build hose assemblies that stand up to rough use. Our mechanical assemblers bend and form steel tubing that would be the envy of custom speed shops.

All of this work is only possible with strong training on hydraulic theory. We make decisions in build that directly impact our machines performance. In order to pinpoint a problem when the machine is powered up and adjust the systems, we need to know why it works, not just connect the plumbing to the right places.

Use the Right Tools for the Job

At UNISIG, we have the tools to work safe without wearing ourselves out. Building machines is physical, but it shouldn’t be hard work. Overhead cranes with modern controls let us assemble massive machines with finesse. Our build floor is planned to have the right tools nearby so we can focus on the job.

After sub-assembly, we use vibration and temperature analysis equipment while we run in rotating assemblies. Builders and engineers work together to establish the guidelines of performance that ensure decades of operation.

When there is a better tool to get the job done, we buy it. The future of mechanical work is to extend our human efforts by working smart. We find what is next.

Machine Testing and Alignment

Building a machine is the first part of the job. The rest of it is making sure everything works. Our mechanical assembly team is deeply involved in the machine function testing and they know how to operate the machines. When everything is checked out, we perform a final power-on alignment to make sure the accuracy over the full range of motion and document the results.

Not all tests go as planned. This is where our understanding of how every part of the machines work come into play. Normally, anything that doesn’t work out of the box is related adjustments and tuning of the machines. It is rare that something gets through our quality checks during the build process.

Automated systems are more complicated, because there may be multiple machines working together with robotics and workpieces are moving. We stay with it and permanently fix anything that comes up so it doesn’t haunt the project and cause problems for our customers.

Machine Demonstration and Applications

The final step in any project before we put it on trucks for shipment is demonstrating the machine to our customers. The mechanical project leader is normally the person directly showing off what the machine can do, and training the customers on good best practices to use it.

Many machines and automated systems are built to achieve a set of performance specifications that allow us to get sign-off from the customers. The mechanical assembly group works with engineers and subject matter experts to pull everything together and prove it works.

Our most experienced builders know to stay calm in the face of early tooling issues or initially falling short on cycle time. We step through these systematically and solve problems, knowing that success will be the outcome. Our guarantee at UNISIG is “it will work.”

UNISIG CORE COMPETENCIES

Mechanical Engineering | Electrical Engineering | CNC Machining | Fabrication | Mechanical Assembly | Electrical Assembly | Precision Calibration | Machine Service | Training