Core Competence – Electrical Engineering

UNISIG machines are smart. The technologies that our team develop change industries. Electrical engineering influences the machine design direction at the outset to make our machines modern, high-performing, and relevant to our customers long after their initial investment is made.

High speed servo motion, regenerative drives, and precision feedback devices define a modern machine tool. Our control engineers design the intelligent, automated machines that are the future.

Electrical Engineering – How we do it better

Our engineers touch every aspect of the machine during the startup and commissioning phases of a project. We get direct and unvarnished feedback from our customers during training events and remote troubleshooting sessions as we support our service group. This experience is essential to developing our good judgment that is needed to design the UNISIG product line.

We are supported by world class industrial hardware manufacturers like Siemens, Heidenhain, and Fanuc, but at UNISIG the solution is ours. We take extreme ownership of our control systems, and we are the last word on what works and what doesn’t. This guides us as we evaluate and implement new technologies that make UNISIG machines the state of the art.

Control Architecture Development

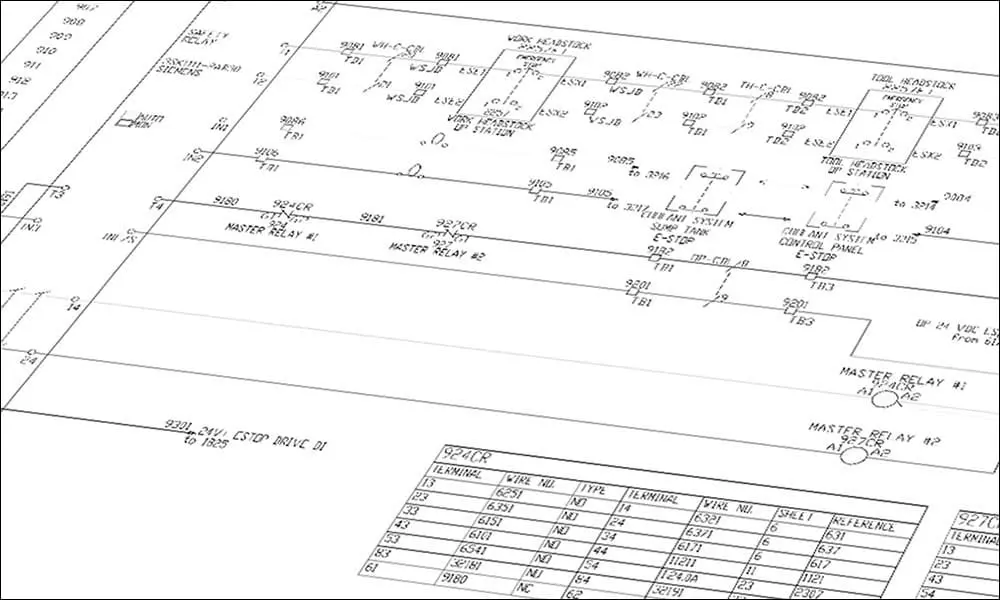

We follow well established engineering guidelines and electrical control regulations to make safe machines that are reliable. That is only the starting point, not the finish line. UNISIG engineers develop concepts for our electrical systems that can be shared across families of equipment, which gives us an edge when we need to do something special or new.

A well-designed control system meets specifications, but it also needs to open up opportunities for the machine to do more for our customers without making it complicated to operate or maintain. Many of our industry leading innovations have come from an electrical engineer at UNISIG seeing a smarter way forward.

Motion Control Engineering

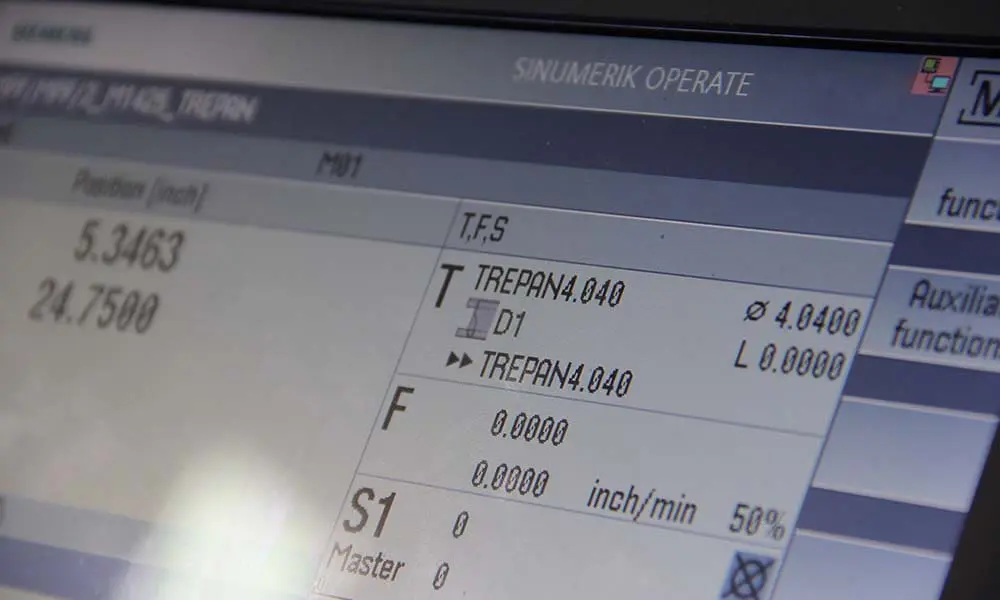

Precision machines need to move. They feed tools into a workpiece with exacting control of position and velocity while a cutting tool does everything it can to push it off the programmed path. While this is happening, real-time, filtered, and relevant information needs to be fed back to the operator or to the machines intelligence to make decisions. This is happening with many servo-axis and spindles in coordination.

Automation needs to move differently. Get from point A to point B in the most efficient, safe and fastest way possible. Also move in synchronization with other changing processes or even other robots performing parallel tasks. UNISIG builds machine tools and automation, and our electrical engineers bring them together.

Hardware Design

UNISIG develops schematics and electrical systems using parametric design software and 3D modeling in the same virtual space as our mechanical engineers. We apply electrical theory and practical design in a way that shortens the engineering cycle and manages our standards to reduce unnecessary variations in our modular approach to systems.

We select hardware suppliers based on their reliability, performance, and our need to service customers around the world. UNISIG has direct access to the hardware vendor engineering teams as a condition of doing business with them, which gives us further insight in design. Our electrical engineers understand how to apply these products in a way that improves their performance while keeping the cost to our customers as low as possible.

Software Design

UNISIG machines use intelligent devices throughout. These devices are networked together and are available for our software to control and use for diagnostics. Our engineers have built software libraries that are used as a basis for new machines so that logic is sound, our machines are reliable, and we can service a large installation base.

The Human Interface aspect of our programming is heavily influenced by our control engineers actual use of the machines. During startup of the equipment, our control engineers learn what our technicians need to troubleshoot issues. Our customers are the best source for our ideas for powerful machines that are still very easy to use.

Machine Commissioning

Engineering is about theory, but the best part is when we get to put it into practice. Our electrical engineers spend time with their creations, working alongside the people that built the machines to power them up, configure devices, connect networks and bring the machines to life.

Once functional, extensive motion control tuning, machine calibration, logic tests and safety checks are performed. This is where the UNISIG electrical engineering team improves how we design our machines and automated systems. Electrical improvements aren’t the only thing discovered through commissioning and testing. Our mechanical teams rely on the electrical engineers to pinpoint areas of concern or opportunities for higher performance through the advanced diagnostics and technology infused in UNISIG products.

Connecting With Our Customers

UNISIG machines are installed around the world. Every one of our machines and automated systems is shipped with a Secure Remote Maintenance System that allows a VPN connection from our factory to the machines running at our customers site.

Our electrical engineers provide troubleshooting assistance to our customers maintenance personal or our own UNISIG field service teams when they are on-site providing maintenance or repair services for our customers.

We learn a great deal about machine reliability and how to improve our designs when we are invited to connect with a machine that has run for many thousands of hours and in some cases millions of cycles.

UNISIG CORE COMPETENCIES

Mechanical Engineering | Electrical Engineering | CNC Machining | Fabrication | Mechanical Assembly | Electrical Assembly | Precision Calibration | Machine Service | Training