Knowledge Center

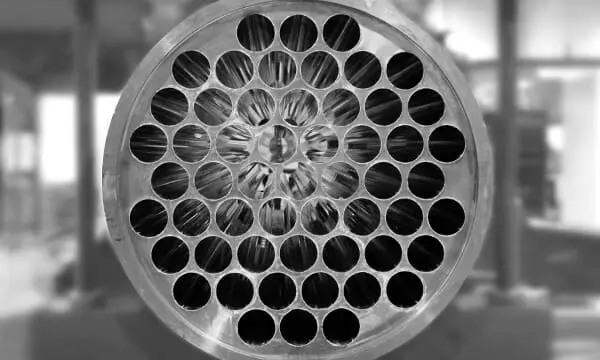

What is Deep Hole Drilling?

Learn what deep hole drilling is, when it’s used, and capabilities across applications.

Search Resources

As appeared in MoldMakingTechnology.com

MSI Mold Builders (MSI) of Cedar Rapids, Iowa, and Greenville, South Carolina, specializes in designing and building large-tonnage prototype and production molds for use in the …

Match Grade Machine, a specialty manufacturer of standard and custom single shot rifle and pistol barrels, stands out in their industry for their exceptional accuracy and attention to detail, complimented with a proven record for fast delivery to customers' hands.

Commercial Tool and Die, plastic injection mold shop in Comstock Park, Michigan, highlights their capabilities in productive deep hole drilling, performed by Ingersoll Deep-Trio tools

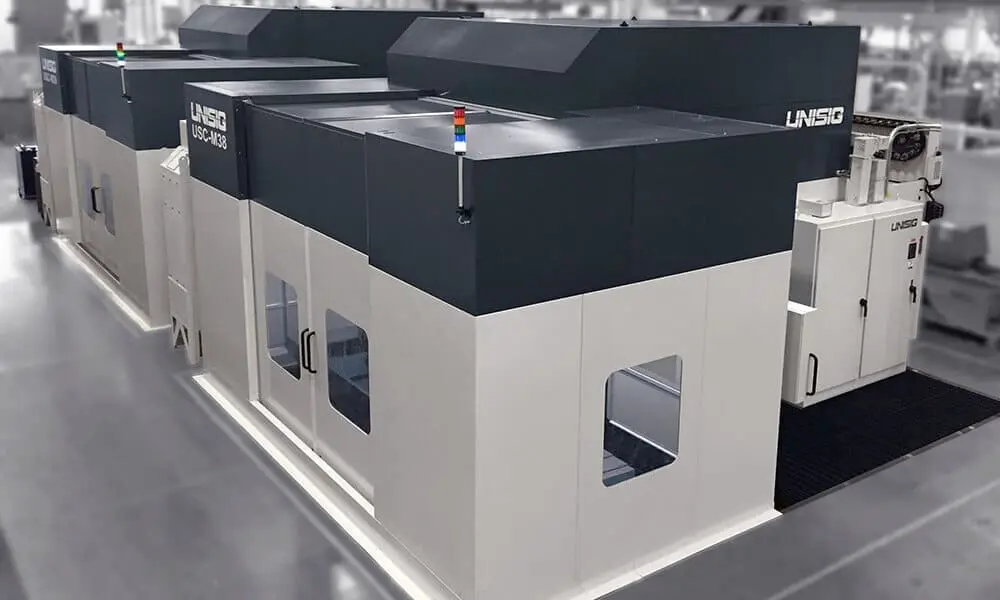

Moldmaking Technology Magazine highlighted Concours Mold Inc.'s investment into UNISIG's USC-M50, and two USC-M38 machines. Concours highlights the reduction of several other machines on their floor

View our customer, Ryerson, discuss their business case for bringing deep hole drilling directly into their facility, and the impact it has on the parts they offer their customers.

William Cook is a UK manufacturer of track running gear for armored vehicles. Their relentless drive to engineer, test, and produce the best products in this category has propelled them to their position as a global industry leader.

When the manufacturing engineering team at medical device manufacturer ConMed, needed to find a way to pull significant costs out of production, he saw an opportunity to bring bone drill holemaking in house

UNISIG introduced a solution that would consolidate multiple gundrilling machines into a UNI25HD multi-spindle machine, replacing several decades-old pieces of equipment to free up floor space,

Alta Precision is an industry-leading manufacturer of commercial aircraft landing gear in Montreal, QC, Canada. When they recently expanded their production facility to introduce a new landing gear product, it was an opportunity to invest in updated capabilities.

USC-M38 machines were configured with a selection of options to benefit productivity and accuracy, including a large tool changer, high precision glass scales, laser presetting, and workpiece probing

UNISIG's solution included application engineering services, as well as machinery, durable tooling, and accessories to meet the customer's goals while reaching unprecedented surface finish levels