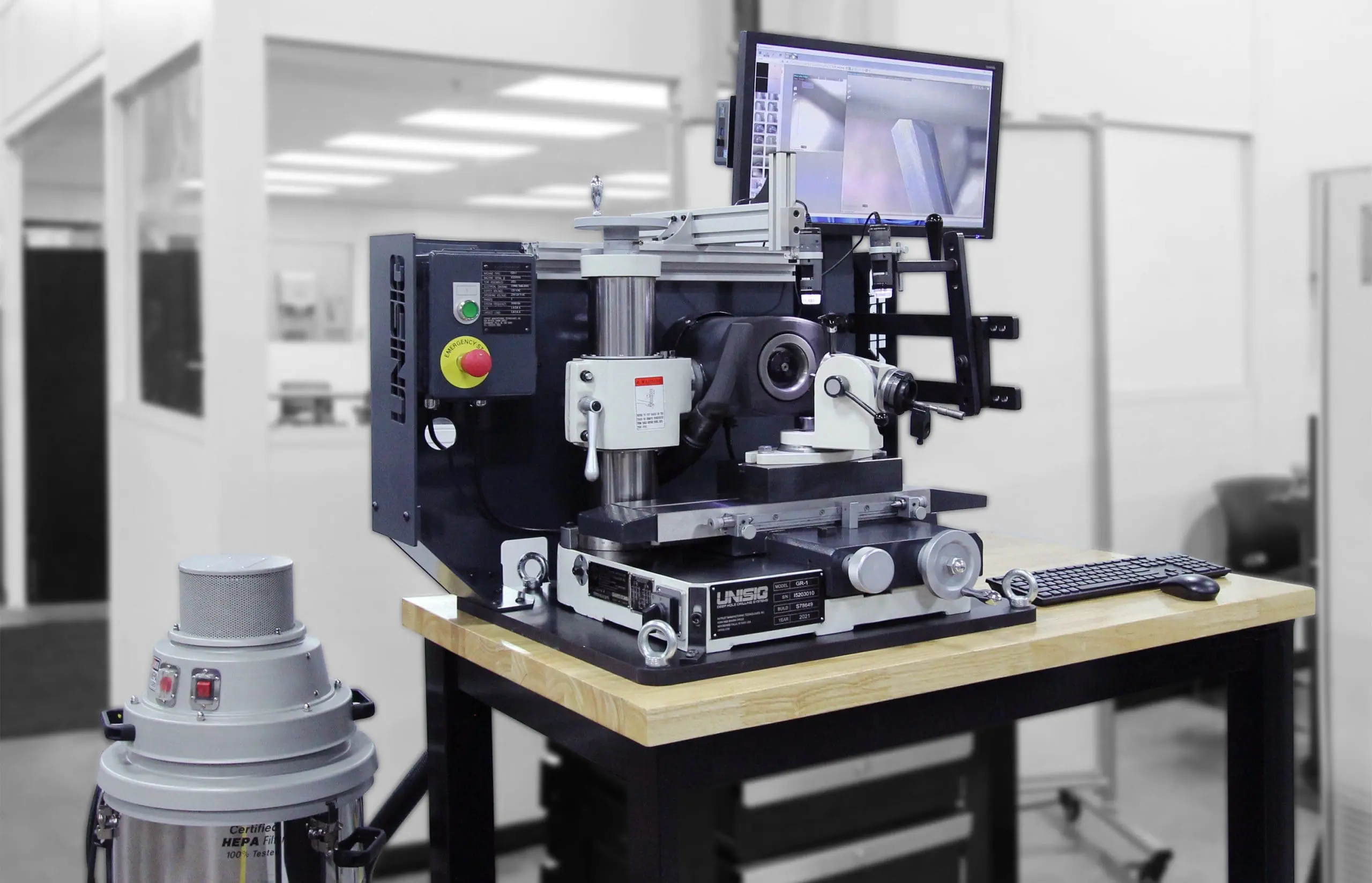

Gundrill Grinder

Complete system for measuring and grinding worn gundrills.

UNISIG’s system provides a complete solution for high quality gundrill grinding and profiling right on your shop floor. Save time and money by regrinding your worn gundrills in-house – controlling both the consistency and the availability of your resharpened tools.

Precision and repeatability in gundrill grinding improves tool life, surface finish, hole size, and straightness – key elements to successful gundrilling. This system provides precision grinding and top-class measurement, also giving you the ability to analyze tool wear and optimize drilling operating parameters.

The Grinder System

- Compact tool and cutter grinding machine, tailored by UNISIG for gundrill grinding

- Digital inspection microscope with measurement software and LED lighting

- Adjustable swing-arm camera mount mechanism for effortless inspection of tool faces and edges

- Computer with inspection software installed, monitor, keyboard and mouse

- Precision grinding fixture with diamond cup wheel

- Base plate mounted for tabletop use; cabinet workbench available as an option

System Benefits

- Easy to use, visual process with results that can be captured for documentation and training

- Inspect gundrills before sharpening as well as afterwards to support process development

- Complete kit includes everything required to productively sharpen gundrills

- Options available to extend range of tool diameters that can be ground

- Grind and inspect tooling in the same setup for the highest accuracy and repeatability of grind

- Application and technical training courses available