Knowledge Center

What is Deep Hole Drilling?

Learn what deep hole drilling is, when it’s used, and capabilities across applications.

Search Resources

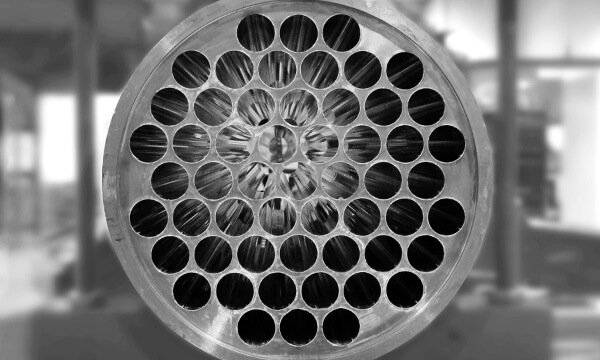

UNISIG UNE Series machines are optimized to allow shops of all sizes to bring gundrilling operations in-house. The twin spindle UNE32-2-1500-CR is packed with features like single spindle mode for extended drilling diameter range, counter-rotation for hole accuracy, programmable coolant delivery, and more.

For precision rifling of barrels up to 4m in length (157 in) and between 20 and 50mm caliber, UNISIG has a capable solution: The R50 rifling machine. With a fully programmable twist rate, barrel manufacturers have excellent control over the rifling process, and exceptional accuracy.

MENOMONEE FALLS, Wis., Aug. 13, 2024 – Representing a leap forward in programming, UNISIG’s next-generation operating system further improves the human-robot interface and slashes programming times.

The new operating system, …

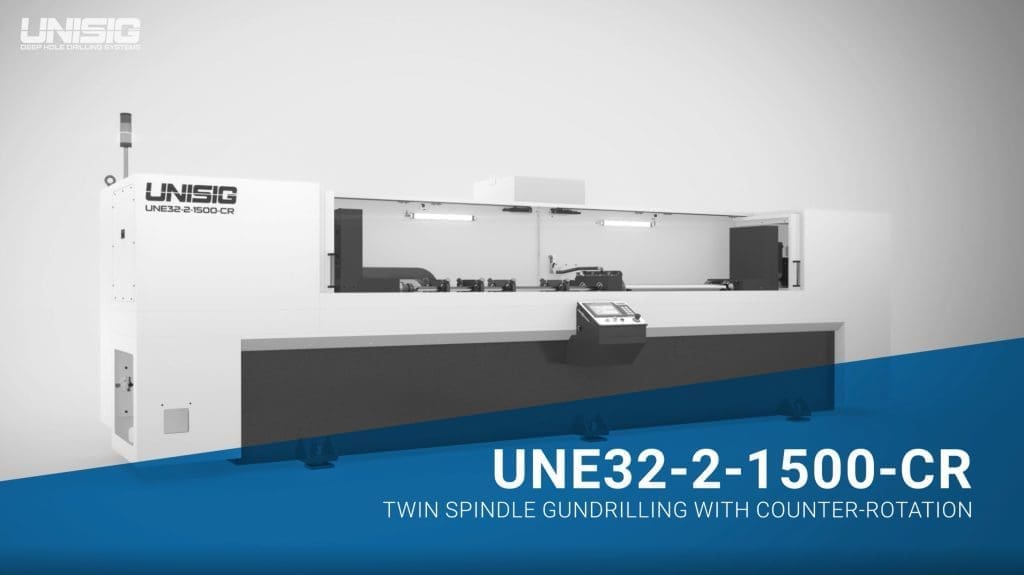

For precision on-center BTA drilling of holes up to 3 meters (10 feet) deep, UNISIG's B380-3M provides the perfect complement to shops with mill-turn capabilities. These compact machines are built for high-power BTA drilling, meeting the highest tolerance standards.

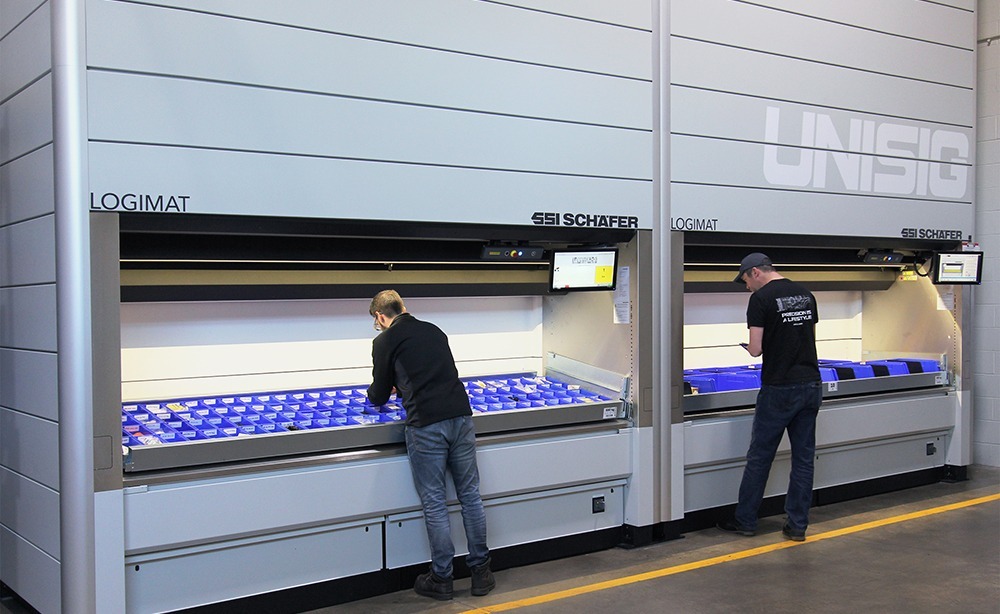

With enhanced customer service in mind, UNISIG, a global manufacturer of deep hole drilling machines, has commissioned two new SSI Schafer LOGIMAT® vertical lift modules (VLM) into its parts warehouse. …

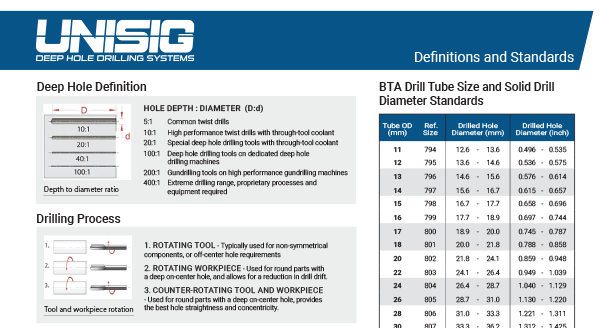

The UNISIG Deep Hole Drilling Technical Reference sheet contains valuable formulas and data. Click the button below to download.

UNISIG’s B-Series gives customers the flexibility and power to perform BTA drilling on large, heavy workpieces. B-Series machines can also work alongside a robot, automating the loading and unloading process which optimizes production by improving floor to floor time. UNISIG B-Series machines are organized into two categories: B-Series < 800 mm swing over bed and B-Series > 800 mm swing over bed.

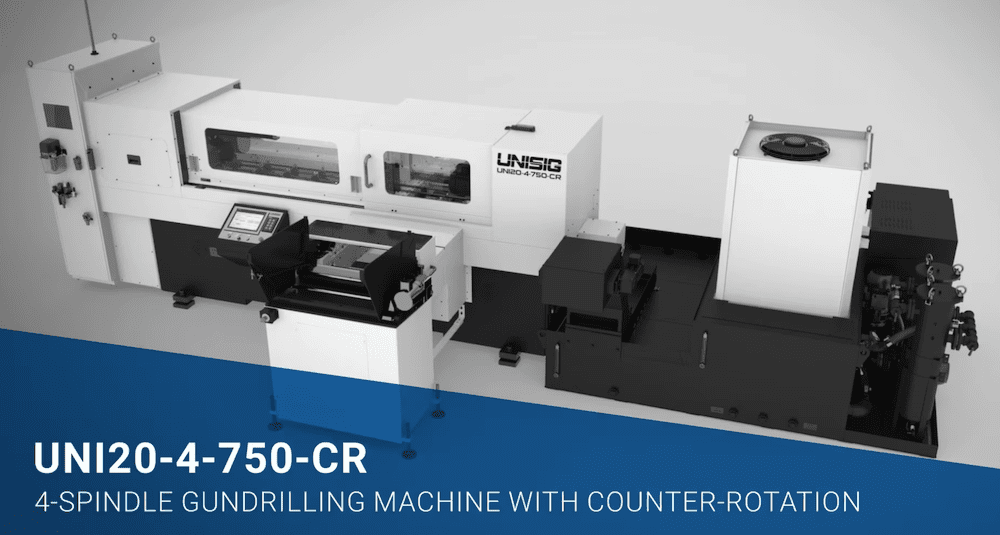

For high-volume gundrilling production with great accuracy, UNISIG's UNI20-4-750-CR has a lot to offer. Four spindles with a max drilling diameter of 20mm (.78 inch) and max depth of 750mm (30 inches) deliver expanded productivity, and the workpiece counter-rotation (CR) improves hole accuracy and straightness.

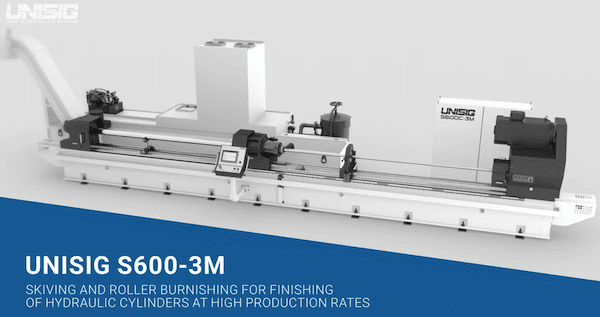

Hydraulic cylinder manufacturers discover improved production rates when using a UNISIG S-Series machine to finish their cylinder interiors. The single-pass skiving and roller burnishing operation is extremely efficient and accurate on these machines, and this S600-3M model example helps to illustrate the features of UNISIGs S-Series.

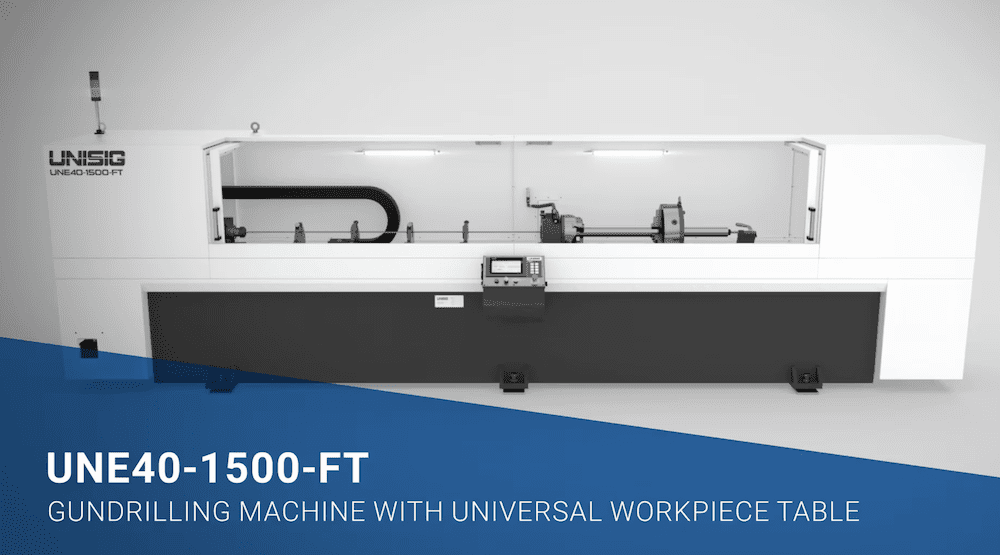

With the flexibility of its universal table for part fixturing, UNISIG’s UNE40-1500-FT deep hole drilling machine offers manufacturers a unique opportunity to bring gundrilling operations in-house.

Deep hole drilling on a production scale meets high accuracy standards with UNISIG's UNI-25BTA-4-750 4-spindle drilling machine.

An overview of the feature-rich UNE12-2-750-CR from UNISIG. Its two spindles are capable of precision gundrilling to 12mm in diameter and 750mm in depth -- at 12,000 rpm, adding a great deal of productivity within a compact footprint. This fully enclosed machine boasts over 2,000 psi coolant pressure with a contained chip collection system and touchscreen control panel. Counter-rotation of cylindrical workpieces ensures improved hole straightness. UNISIG builds this gundrilling machine to be automation-ready, and frequently integrates robots with its products.