What is Gun Drilling?

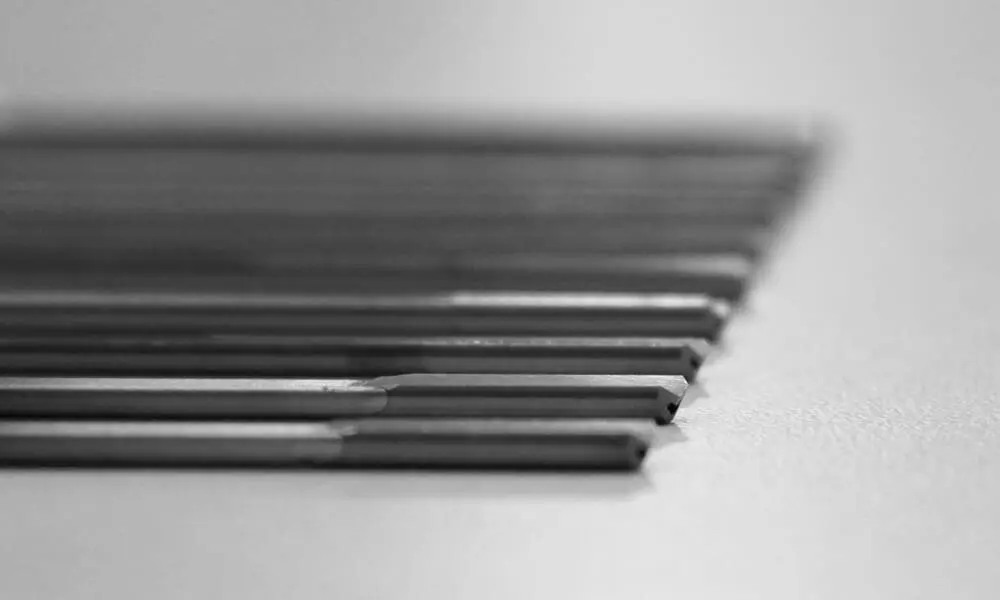

Gundrilling is a deep hole drilling process that uses a long, thin cutting tool to produce holes in metal at high depth-to-diameter ratios. Gun drilling is effective in diameters from 1 – 50 mm [0.04 – 2.00 in]. A gundrill tool differs from a conventional twist drill by its unique head geometry; a standard gundrill has a single effective cutting edge that removes chips as it advances into a metal workpiece.

Gundrilling is a deep hole drilling process that uses a long, thin cutting tool to produce holes in metal at high depth-to-diameter ratios. Gun drilling is effective in diameters from 1 – 50 mm [0.04 – 2.00 in]. A gundrill tool differs from a conventional twist drill by its unique head geometry; a standard gundrill has a single effective cutting edge that removes chips as it advances into a metal workpiece.

The gundrilling process is able to drill deep holes beyond what is possible with conventional machinery and tooling such as twist drills, by using high pressure coolant for clean chip exhaust, even at extreme depths.

Gun drilling was initially developed for the manufacture of gun barrels, where both straightness and barrel durability were essential to properly functioning barrels. The gundrilling process and tooling have been refined for maximum performance and use on modern, dedicated machinery. Firearms continue to be a common application for gundrilling. Other industries include diesel fuel components, medical tooling, plastic injection molds, and more.

Gun drilling was initially developed for the manufacture of gun barrels, where both straightness and barrel durability were essential to properly functioning barrels. The gundrilling process and tooling have been refined for maximum performance and use on modern, dedicated machinery. Firearms continue to be a common application for gundrilling. Other industries include diesel fuel components, medical tooling, plastic injection molds, and more.

Gun drilling can be done, with limited performance, on common CNC machines. Holes with a depth-to-diameter ratio of 20:1 or greater generally require dedicated equipment to achieve the highest productivity and process reliability, and can reach extreme ratios of 400:1 or greater.

Gun Drilling vs BTA Drilling

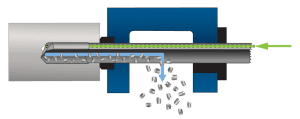

The gun drilling process is ideal for smaller hole diameters, up to 50 mm [2.00 in]. The gun drilling process differs from BTA drilling due to coolant entry and chip removal; gundrills introduce coolant internally through a small hole within the tool, and chips are removed by coolant through a groove outside the length of the tool. BTA drilling machines introduce coolant externally, through an assembly around the tool, while chips are evacuated through the drill itself.

Optimal Specifications for Gun Drilling Process

Gun drilling is the ideal process for a range of deep hole drilled depths and diameters. Extremely deep holes and small diameter holes utilize gundrilling with specific equipment to maintain straightness and precision.

Gun Drilling Diameters

| 1 – 3 mm | Possible with proper equipment |

| 3 – 25 mm | Common |

| 25 – 50 mm | Common |

| 50 – 75 mm | Possible, but less productive than BTA drilling |

Gun Drilling D:d Ratios

| 5:1 | Common twist drills |

| 10:1 | High performance twist drills with through-tool coolant |

| 20:1 | Special deep hole drilling tools with through-tool coolant |

| 100:1 | Gundrilling tools on dedicated gundrilling machine |

| 200:1 | Gundrilling tools on high performance gundrilling machine |

| 400:1 | Extreme drilling range, proprietary processes and equipment required |

Gun Drilling Equipment

Gundrilling machines are engineered and built to achieve desired tolerances in deep holes. View a machine diagram and learn about the high-precision components that make up gundrilling equipment.

Learn more >

Gundrilling tools are chosen and integrated into the deep hole drilling system to achieve the highest tolerance standards possible.