May

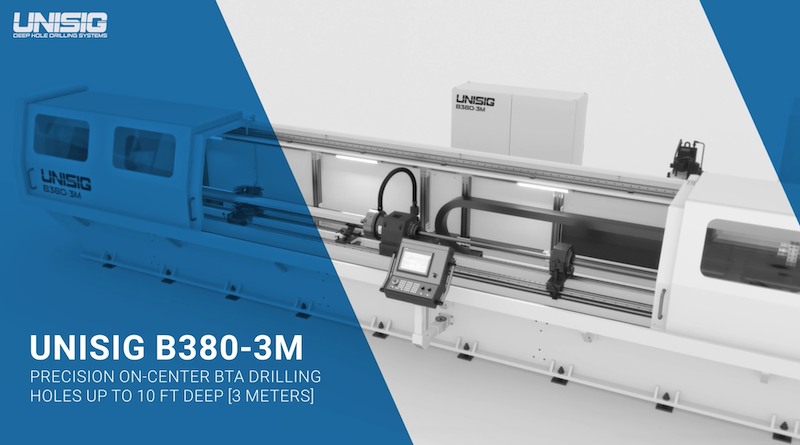

UNISIG B380-3M Features

- 2024

- Philipp

For precision on-center BTA drilling of holes up to 3 meters (10 feet) deep, UNISIG’s B380-3M provides the perfect complement to shops with mill-turn capabilities. These compact machines are built for high-power BTA drilling, meeting the highest tolerance standards. Use this link to read more about B-Series deep hole drilling machines.