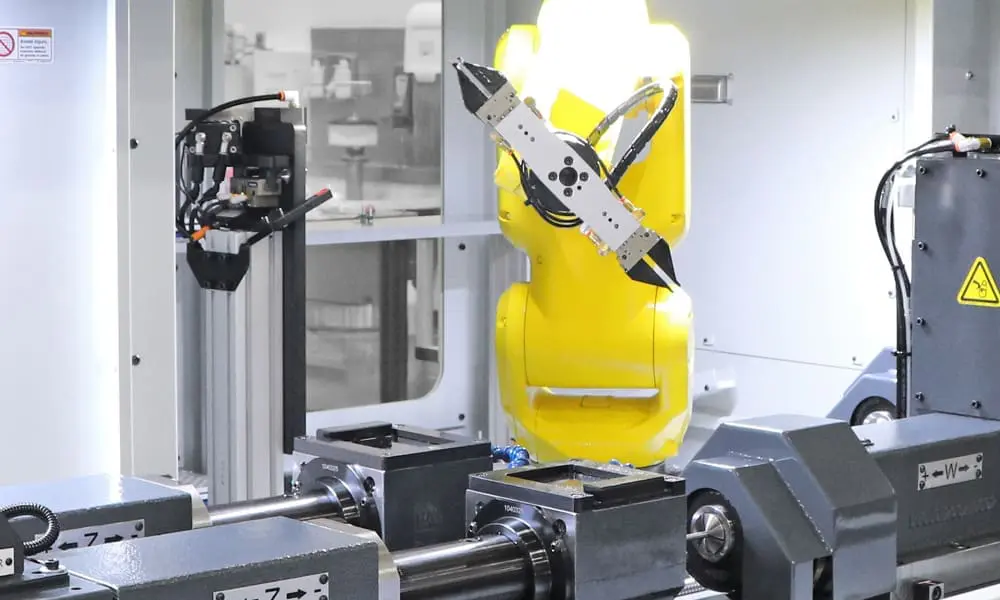

UNE6 Gundrilling Machines for Medical Manufacturing

UNE6 machines are designed so that medical manufacturers can accurately and productively gundrill components after Swiss machine turning. Companies producing medical components such as orthopedic tooling can change their approach to manufacturing, reduce dependency on cannulated materials, and expand their own capabilities with UNISIG.

Our UNE6 medical gundrilling machines are specifically designed for the challenges and dimensions faced by medical manufacturers. Machines are capable of holes from 0.8 – 6.0 mm [0.03 – 0.24 in], even in challenging medical grade materials. Automation options, and a 2 independent spindle configuration allow manufacturers to find a solution that perfectly fits their needs.

| Description | UNE6 | UNE6-2i |

|---|---|---|

| Number of spindles | 1 | 2 independent |

| Hole diameter minimum | 0.8 mm | 0.8 mm |

| Hole diameter maximum | 6.0 mm | 6.0 mm |

| Part length maximum | 750 mm | 250 or 750 mm |

| Tool spindle speed maximum | 24,000 rpm | 24,000 rpm |

| Work spindle speed maximum | 4,000 rpm | 4,000 rpm |

| Combined drilling speed maximum | 28,000 rpm | 28,000 rpm |

| Coolant pressure maximum | 207 bar | 207 bar |

| Description | UNE6 | UNE6-2i |

|---|---|---|

| Number of spindles | 1 | 2 independent |

| Hole diameter minimum | 0.03 in | 0.03 in |

| Hole diameter maximum | 0.24 in | 0.24 in |

| Part length maximum | 30 in | 10 or 30 in |

| Tool spindle speed maximum | 20,000 rpm | 20,000 rpm |

| Work spindle speed maximum | 4,000 rpm | 4,000 rpm |

| Combined drilling speed maximum | 24,000 rpm | 24,000 rpm |

| Coolant pressure maximum | 3,000 psi | 3,000 psi |