Feb

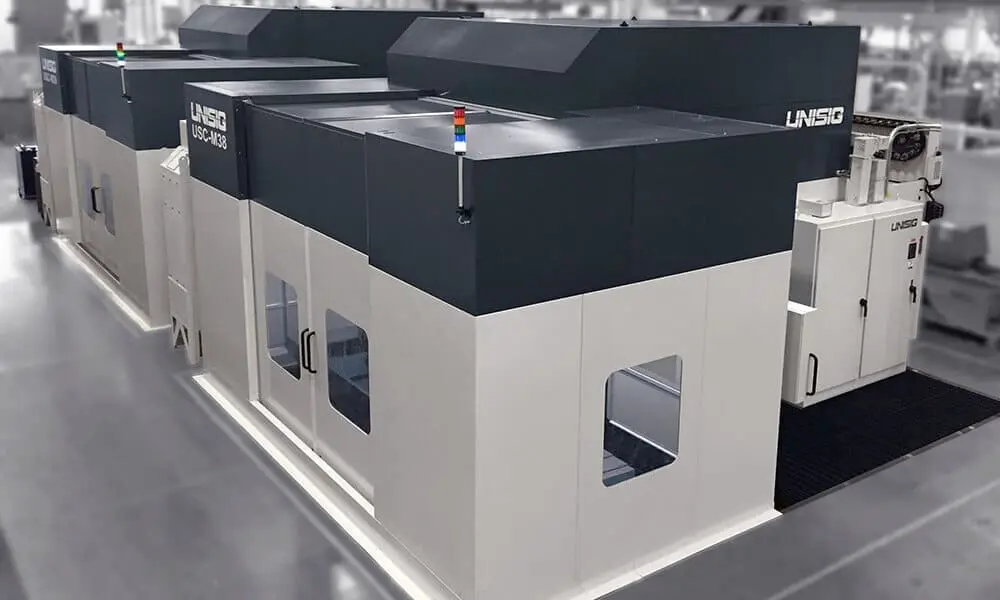

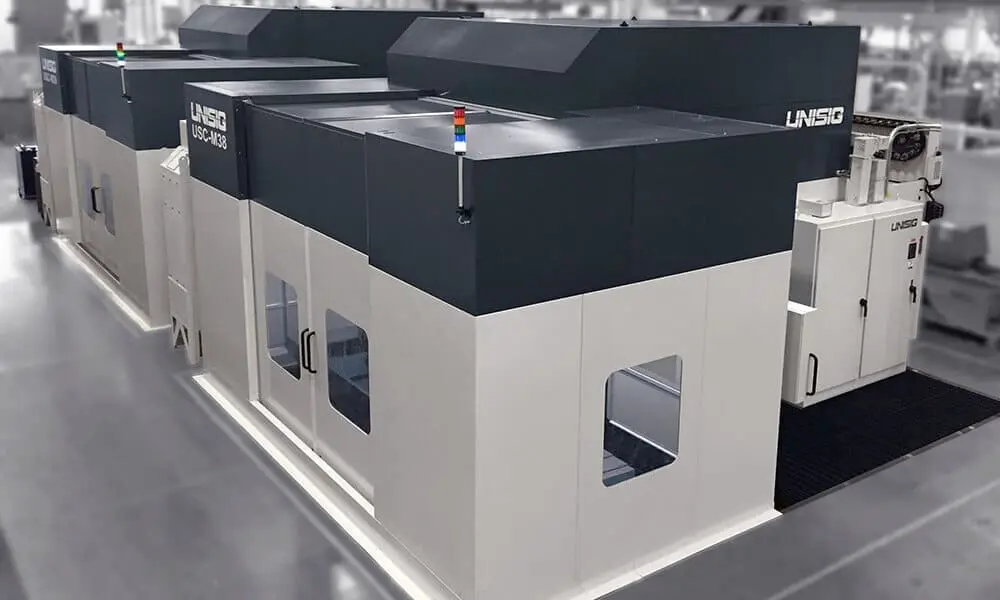

Making a Mold Impact

- 2015

- Anthony Fettig

Industry: Mold, Automotive

Customer Product: Plastic Injection Mold Tooling

UNISIG Solution: USC-M38 Mold Drilling and Machining Center

Feb

Industry: Mold, Automotive

Customer Product: Plastic Injection Mold Tooling

UNISIG Solution: USC-M38 Mold Drilling and Machining Center

Mar

Industry: Off-Highway, Agriculture

Customer Product: Hydraulic Cylinders

UNISIG Solution: S600 Skiving and Roller Burnishing Machine

A world leading US company that produces heavy duty hydraulic cylinders needed to modernize its cylinder production of over 700 unique cylinder models. Surface finish requirements and production requirements were key factors, both of which were vital across the range of cylinder diameters and sizes.

UNISIG’s solution included application engineering services, as well as machinery, durable tooling, and accessories to meet the customer’s goals while reaching unprecedented surface finish levels. The project included extensive training for teams of engineers and operators, enabling the customer to achieve their cylinder manufacturing requirements in this challenging production environment.

The project included an initial purchase of six UNISIG S600C machines, capable of bores up to 200 mm in diameter, and 3,000 mm long, installed in both the USA and Mexico, where they are currently in operation and upholding the requirements of hydraulic cylinder manufacturing.