Machines with BTA Drilling Capabilities

BTA deep hole drilling is a process that accurately drills holes from 20 – 630 mm [0.80 – 24.0 in] in diameter with higher feed rates. BTA drilling uses external coolant introduction and internal chip removal for precision drilling performance, even at extreme depths-to-diameter ratios.

Find a machine for BTA drilling

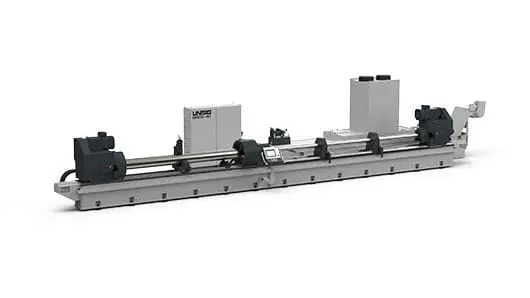

UNI machines perform deep hole drilling in production environments. These machines are modularly configured, and often add automation, for the ultimate in efficiency and accuracy.

Designed for:

- Gundrilling and/or BTA

- Hole Diameters up to 50 mm [2.00 in]

- Round Workpieces

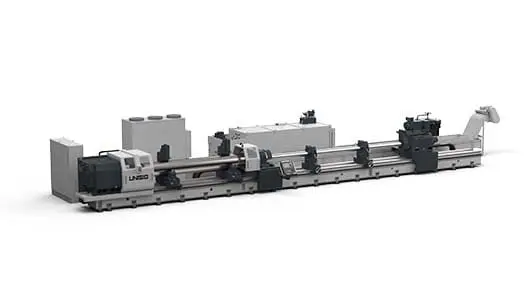

These B-Series deep hole drilling machines use BTA drilling and related tools to produce accurate centerline holes up to 300 mm [12.0 in] in diameter.

Designed for:

- BTA

- Hole Diameters up to 300 mm [12.0 in]

- Hole Depths up to 10 m [32.0 ft] or more

- Round Workpieces

B-Series machines can handle the drilling of longer workpieces without sacrificing accuracy. These machines are capable of hole diameters up to 630 mm [24.8 in], up to 20,000 mm [65.5 ft] deep.

Designed for:

- BTA

- Hole Diameters up to 630 mm [25.0 in]

- Hole Depths up to 20,000 mm [65.5 ft]

- Round Workpieces

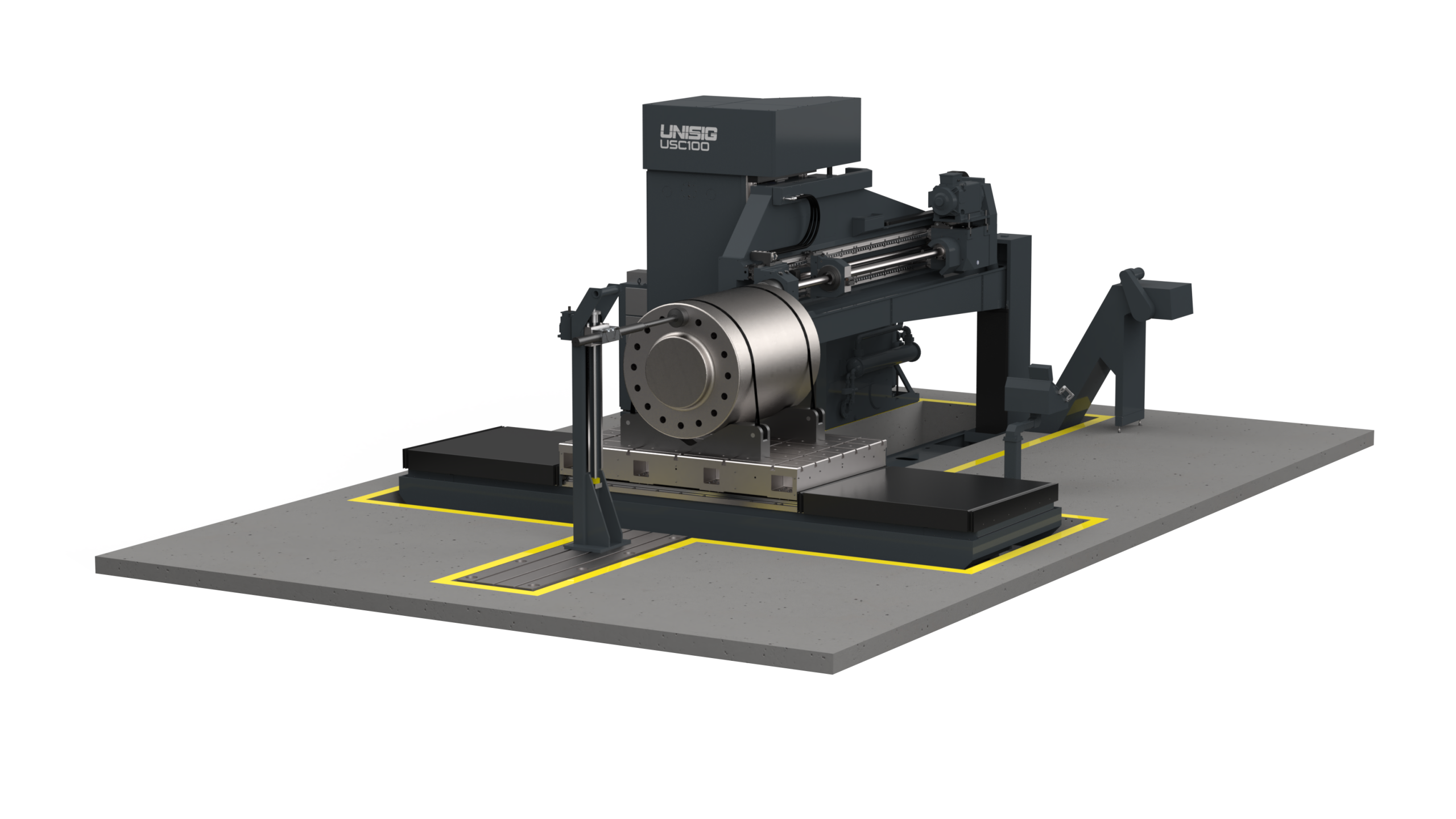

USC series column-type machines handle larger, heavier workpieces with rigidity and accuracy

Designed for:

- BTA

- Hole Diameters up to 102 mm [4.00 in]

- Block Workpieces

USC-M series machines combine deep hole drilling and milling in a single machine, for significant improvements in capability and throughput.

Designed for:

- Gundrilling or BTA

- Hole Diameters up to 50 mm [2.00 in]

- Block Workpieces

- Mold Industry Applications

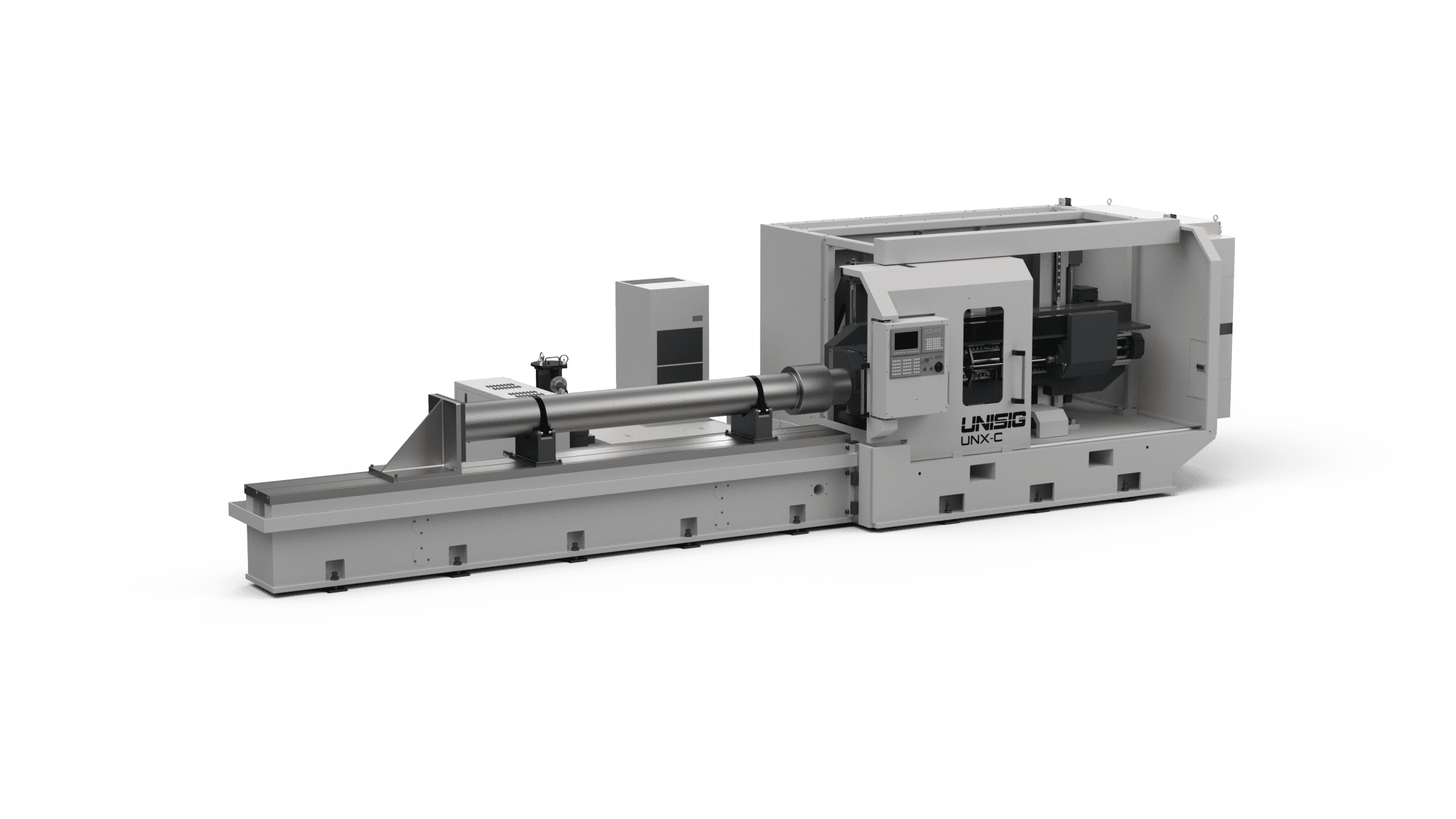

The UNX series is designed to meet the challenges of off-center holes with extreme depth-to-diameter ratios.

Designed For:

- Gundrilling and BTA

- Hole Diameters up to 50 mm [2.00 in]

- Hole depths up to 3,000 mm [118 in]

- Workpiece length up to 10,000mm [32.8 ft]