Machines with Milling and Machining Capabilities

Certain UNISIG machine models incorporate milling and machining to complement precision deep hole drilling. Added dynamic machining capabilities result in reduced setups and improved profitability when producing complex workpieces from start to finish. Milling, drilling, tapping, thread milling, boring, contouring, and other CNC machining operations, as well as up to 5-axis positioning, are productive on a UNISIG drilling and machining center.

Find a machine for Milling and Machining

USC-M series machines combine deep hole drilling and milling in a single machine, for significant improvements in capability and throughput.

Designed for:

- Gundrilling, BTA, Machining

- Hole Diameters up to 50 mm [2.00 in]

- Block Workpieces

- Mold Industry Applications

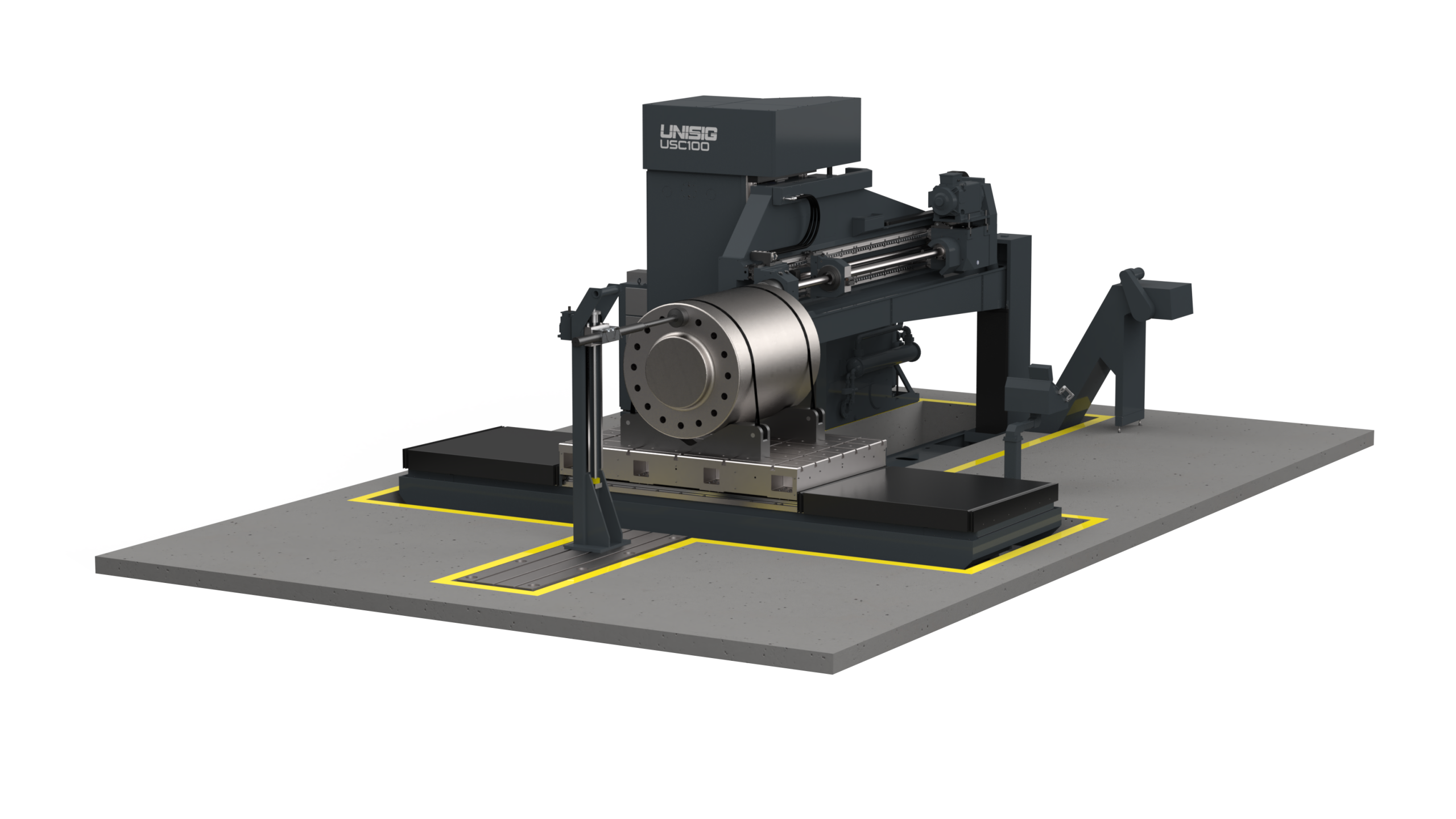

USC series column-type machines handle larger, heavier workpieces with rigidity and accuracy

Designed for:

- BTA, Machining

- Hole Diameters up to 102 mm [4.00 in]

- Block Workpieces