Knowledge Center

What is Deep Hole Drilling?

Learn what deep hole drilling is, when it’s used, and capabilities across applications.

Search Resources

One of the most surprisingly productive ways to achieve high quality bore finishing in OEM production. Even experienced machinists are impressed when they see raw tubing converted into a mirror-like finish in a single pass at extremely high feed rates. This is achieved by combining two operations into a single tool and having the right machine for the job.

Mechanically efficient designs run cooler, hold tighter tolerances, and last longer. UNISIG machines are engineered with this in mind. Axis drives use direct-drive servos or high-efficiency planetary gear reducers rather than worm drives or belts on axis drives. Our high-powered geared headstocks use precision-ground, constant-mesh helical gearing, and pumped synthetic lubrication to reduce friction and improve power transmission efficiency.

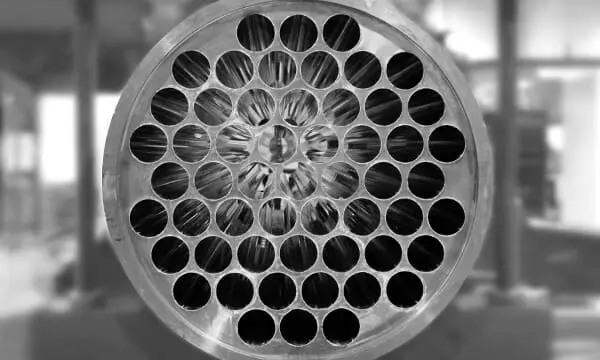

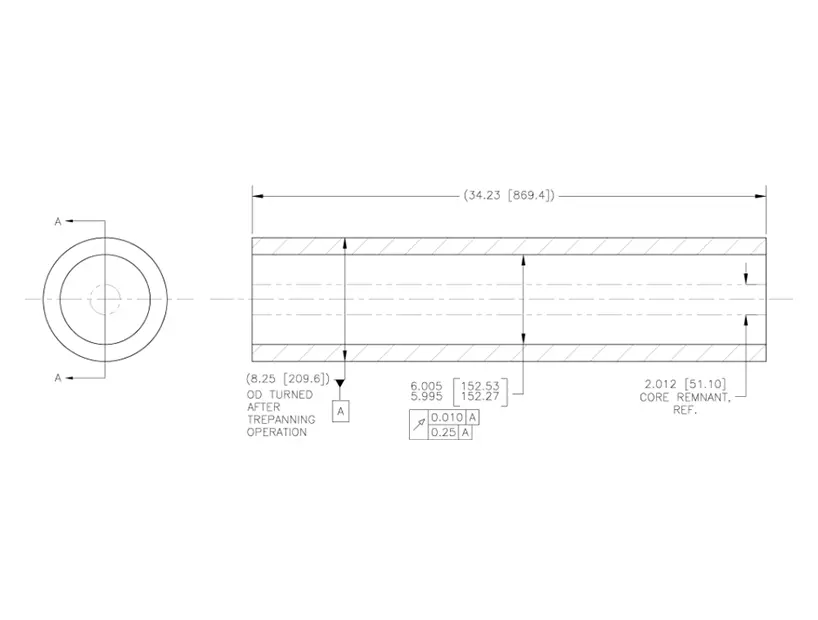

Trepanning is a process used to create a hole in a workpiece by machining only the outer area of the hole, leaving an unmachined core in the center. A BTA drill creates the same hole by turning all of the material into chips, leaving no core behind. This gives manufacturers two distinct ways to create a hole from solid material.

We want our machines to look good while they age. Part of our strategy for this is to use a two-component polyurethane enamel to paint our base castings, structural frames, machine enclosures, or any fabricated metal parts in our machines. Recently, we targeted our painting department for investment to keep up with our growing company and expanding product line.

Every company that builds advanced technology products is chasing engineering innovation, looking for clever and practical designs that separate them from the competition. Precision machine tools and automation have evolved to incredible levels because of constant competitive pressure, but that same pressure can leave design engineers searching for fresh inspiration.

Automation is part of our DNA at UNISIG. Many of our deep hole drilling machine projects include some level of automation, and we think about it at every step of development. This approach allows us to offer customers automation options with their initial purchase or as a future upgrade, ensuring their investment is compatible with automated production.

Landmann has managed UNISIG’s Midwest sales region for over a decade, during which his success has helped strengthen the company's worldwide reputation for delivering robust, customer-focused solutions to deep hole drilling applications.

UNISIG designs and builds deep hole drilling machines and automation systems. We provide the latest tools, equipment, and technology so our skilled team can take pride in their work and enjoy producing high-precision machines. One of those tools is our hand-held laser welder.

Precision, automation, and efficiency are redefining medical instrument manufacturing. When one manufacturer faced the challenge of producing complex surgical components with extreme accuracy and depth-to-diameter ratios over 100:1, they turned to UNISIG.

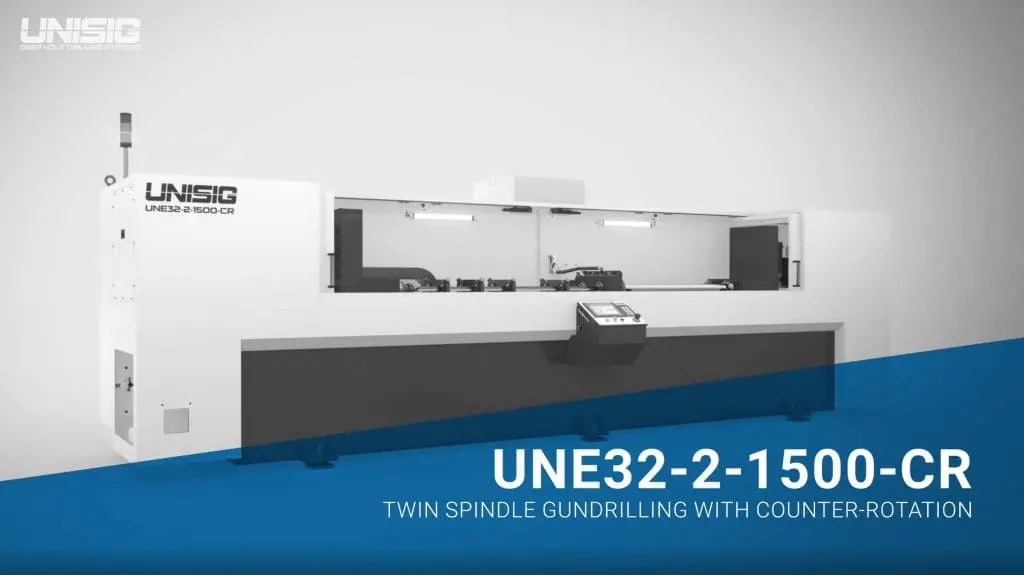

UNISIG UNE Series machines are optimized to allow shops of all sizes to bring gundrilling operations in-house. The twin spindle UNE32-2-1500-CR is packed with features like single spindle mode for extended drilling diameter range, counter-rotation for hole accuracy, programmable coolant delivery, and more.

For precision rifling of barrels up to 4m in length (157 in) and between 20 and 50mm caliber, UNISIG has a capable solution: The R50 rifling machine. With a fully programmable twist rate, barrel manufacturers have excellent control over the rifling process, and exceptional accuracy.

MENOMONEE FALLS, Wis., Aug. 13, 2024 – Representing a leap forward in programming, UNISIG’s next-generation operating system further improves the human-robot interface and slashes programming times.

The new operating system, …