Mechanically efficient designs run cooler, hold tighter tolerances, and last longer. UNISIG machines are engineered with this in mind. Axis drives use direct-drive servos or high-efficiency planetary gear reducers rather than worm drives or belts on axis drives. Our high-powered geared headstocks use precision-ground, constant-mesh helical gearing, and pumped synthetic lubrication to reduce friction and improve power transmission efficiency.

ENERGY EFFICIENCY AT UNISIG

- Posted on

- Ampersand Milwaukee

Energy efficiency is one area where everyone can agree. It is beneficial for the planet and for profits. A small gundrilling machine may have less than 20 horsepower, while a large BTA drilling machine can exceed 200 horsepower. Regardless of size, every kilowatt-hour of electricity matters. UNISIG designs machines with efficiency in mind because we believe that is how well-planned, modern machines should be built—through thoughtful engineering and design choices that reduce energy consumption and improve performance.

DESIGNING FOR MECHANICAL EFFICIENCY

DESIGNING FOR MECHANICAL EFFICIENCY

"Mechanically efficient designs run cooler, hold tighter tolerances, and last longer."

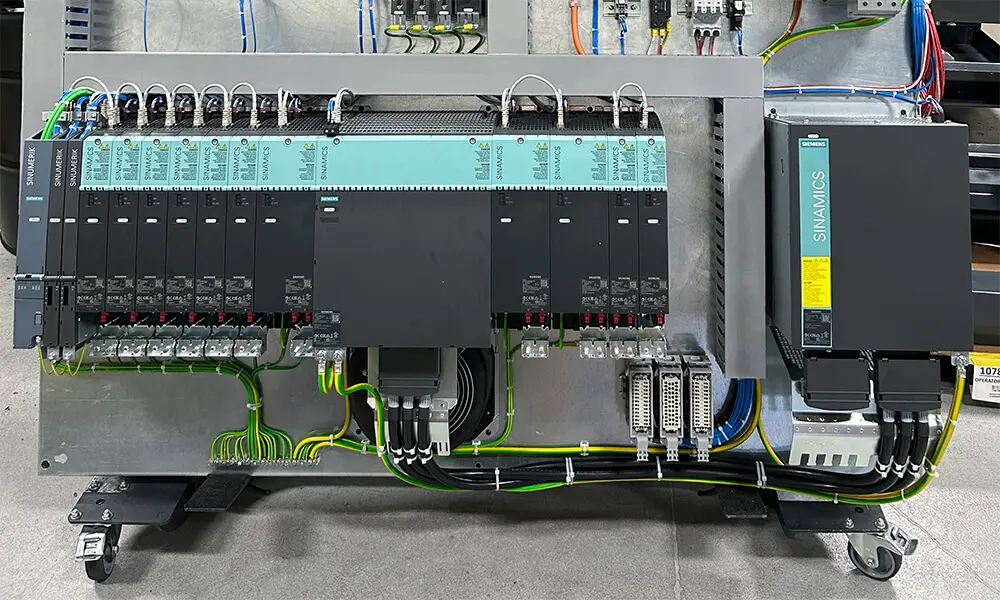

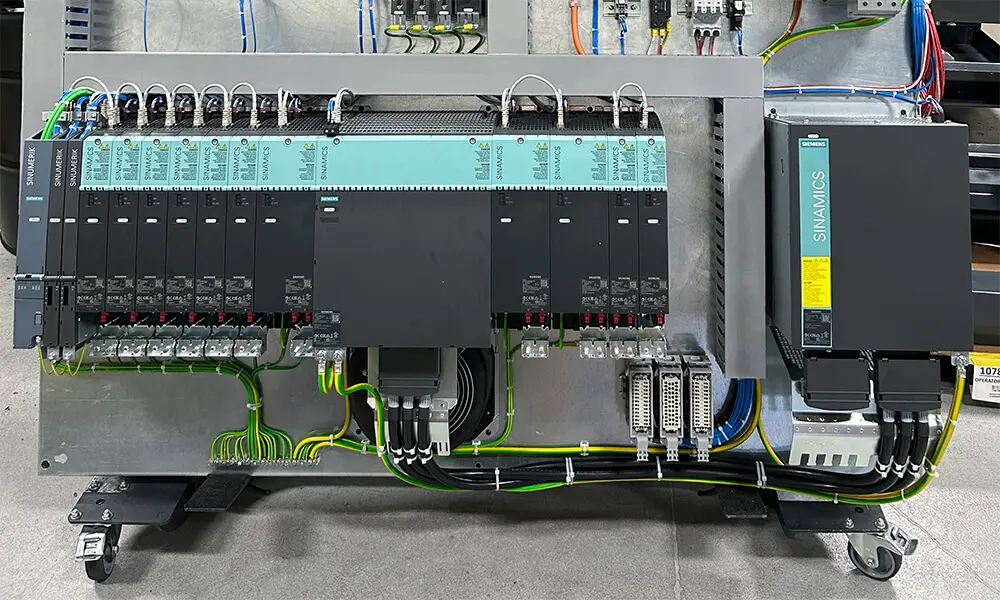

SMART SYSTEMS THAT CONSERVE ENERGY

COMMITMENT BUILT INTO EVERY MACHINE

SMART SYSTEMS THAT CONSERVE ENERGY

COMMITMENT BUILT INTO EVERY MACHINE

FREQUENTLY ASKED QUESTIONS

Because efficiency impacts both performance and sustainability. Well-designed, efficient machines reduce waste, lower operating costs, and improve reliability.

They recover kinetic energy and, in many cases, return high-quality power to the grid.

Yes, positively. Efficient designs reduce heat, maintain precision, and extend component life, leading to improved accuracy and uptime.