Make Better Molds – Mill Better, Drill Faster

- Posted on

- Ampersand Milwaukee

Mold making isn’t easy. There are many intricate challenges that include: highly complex geometry with 2D and 3D features, managing a wide range of part sizes, and short lead times on small quantities and new designs with no room for error. Compounding these challenges is the pressure to keep up with the rapid pace of demand and technology.

Mold making isn’t easy. There are many intricate challenges that include: highly complex geometry with 2D and 3D features, managing a wide range of part sizes, and short lead times on small quantities and new designs with no room for error. Compounding these challenges is the pressure to keep up with the rapid pace of demand and technology.

But there’s a way to overcome those obstacles: Do better work with technology designed specifically for complex mold making.

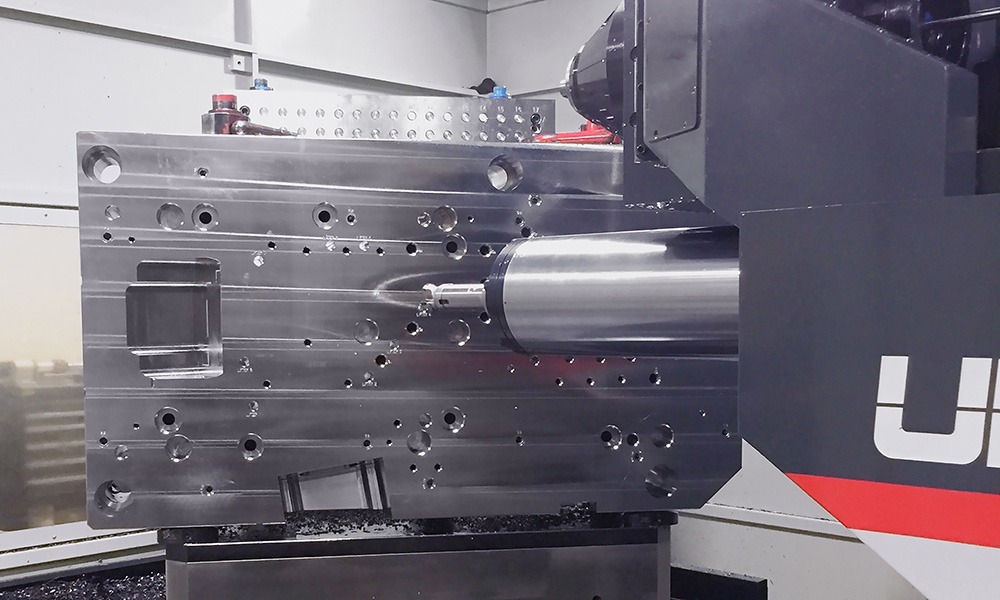

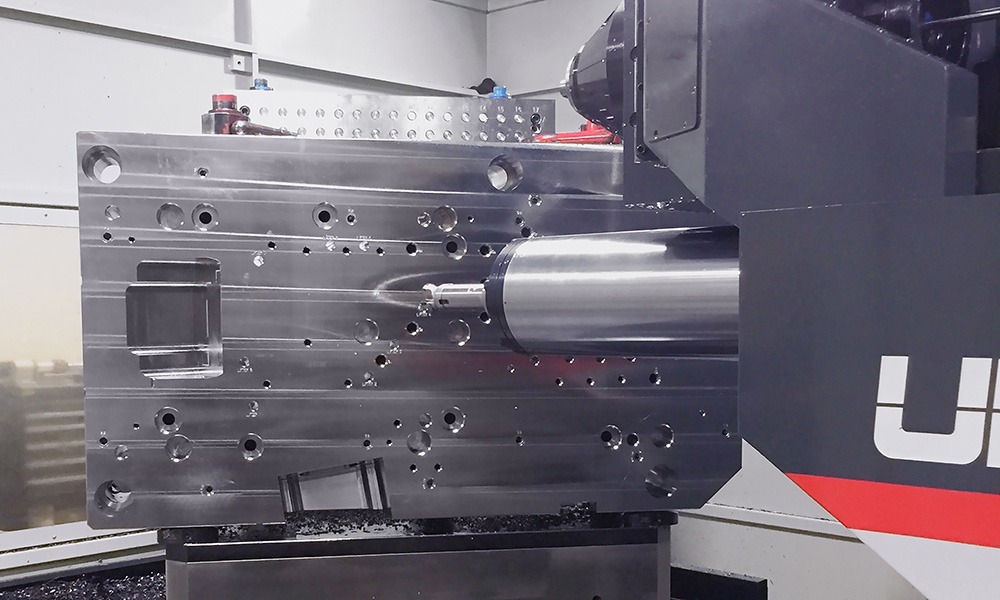

Our USC-M series Milling and Drilling Centers allow you to drill faster and mill better with a single machine and fewer setups. These Milling and Drilling Centers meet the challenges of milling and gundrilling all types of metals with either a single universal combination spindle or dedicated milling and drilling spindles. Utilizing high performance spindles that provide exceptional rigidity and power transmission, these machines deliver high-torque milling capability for aggressive metal removal and shorter cycle times. Additionally, 5-axis positioning enables mold manufacturers to tackle complex geometries with exacting precision in a single setup.

Many manufacturers claim to provide milling and drilling in a single machine, but the truth is those hybrid machines neither mill nor drill well enough to make a significant difference in either operation. In effect, one process is an afterthought of the other. Our USC-M series, however, was designed from the beginning to be a single machine with superior milling and drilling performance and accuracy. State-of-the-art milling technology is embedded into a machine that has the power, thrust, speed and process monitoring competitors thought would be difficult to attain, or simply not possible.

In addition to superior quality and accuracy, the pay-off for single setup milling and drilling is efficiency and an improved bottom line. Mold makers cut delivery times to their customers with faster setups and production along with reduced overall labor costs. Once they move away from mold making operations with two machines, most of our customers find they can’t afford to manufacture without a USC-M-series Milling and Drilling Center.

The benefits of milling better and drilling faster with USC-M series machines do not stop at the spindle. There are intangible benefits as well. UNISIG USC-M series Milling and Drilling Centers allow mold manufacturers to approach their work differently and explore different approaches to mold making. With the entire manufacturing process streamlined, customers find their engineers and design teams enjoy more freedom and flexibility with the expanded capabilities. Finishing and assembly are faster because the design is more efficient, and manufacturers can do things effortlessly that were a struggle previously.

Ultimately, it’s about setting the bar high and keeping it there. UNISIG sets a standard looked up to by the competition. It’s a state-of-the-art mindset that takes mold finishing to a new level with a machine that allows you to mill better and drill faster.

Learn more about UNISIG solutions for Mold manufacturing.