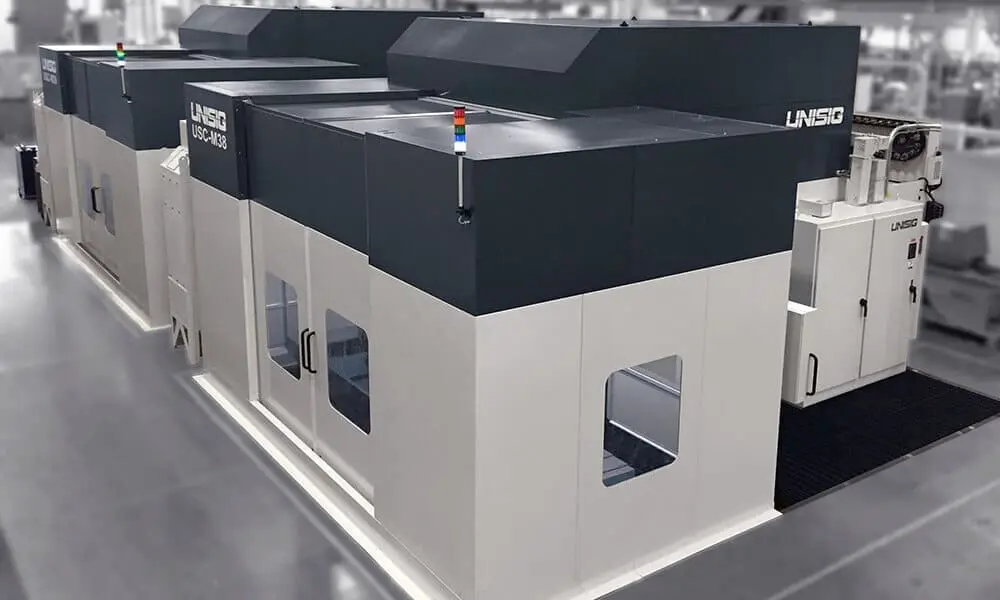

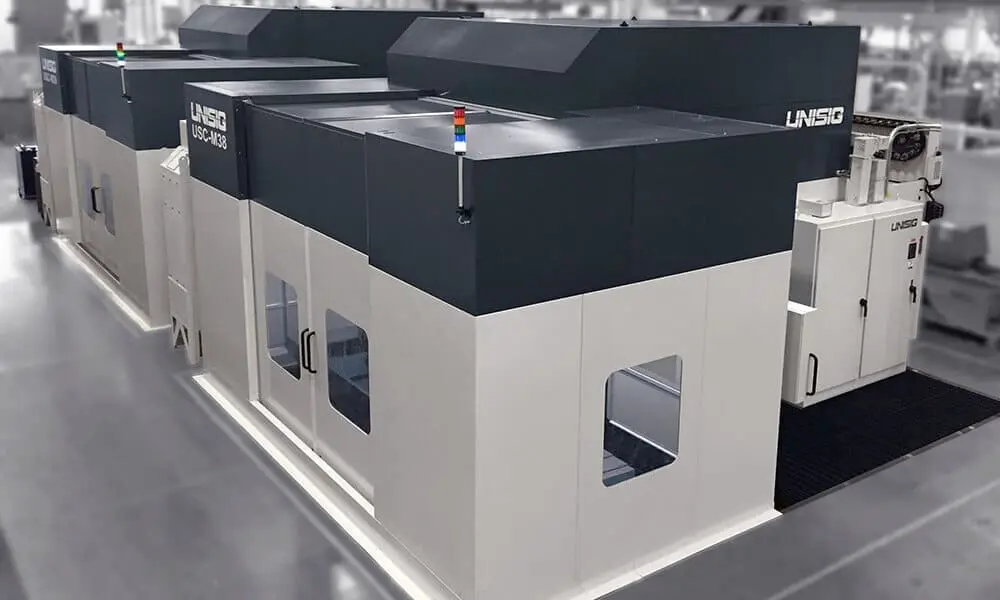

USC-M38 machines were configured with a selection of options to benefit productivity and accuracy, including a large tool changer, high precision glass scales, laser presetting, and workpiece probing

Making a Mold Impact

- Posted on

- Anthony Fettig

Industry: Mold, Automotive

Customer Product: Plastic Injection Mold Tooling

UNISIG Solution: USC-M38 Mold Drilling and Machining Center

A major manufacturer of plastic injection molds needed to upgrade their deep hole drilling capabilities, and viewed their investment as an opportunity to evaluate their current process and find additional opportunities for improvement. After extensive discussions of their current process and future production goals, UNISIG reviewed the impact of a machine that could both mill and drill reliably while reducing setups.

USC-M38 machines were configured with a selection of options to benefit productivity and accuracy, including a large tool changer, high precision glass scales, laser presetting, and workpiece probing. These, along with 50 taper milling, BTA drilling, and gundrilling, provided a solution that surpassed the customer’s expectations.

The customer initially purchased 2 machines, and after beginning to experience manufacturing benefits, added a third, identical machine, to help support their increased throughput, and continue to help them win bids in the mold industry.