USC-M Milling and Drilling Centers

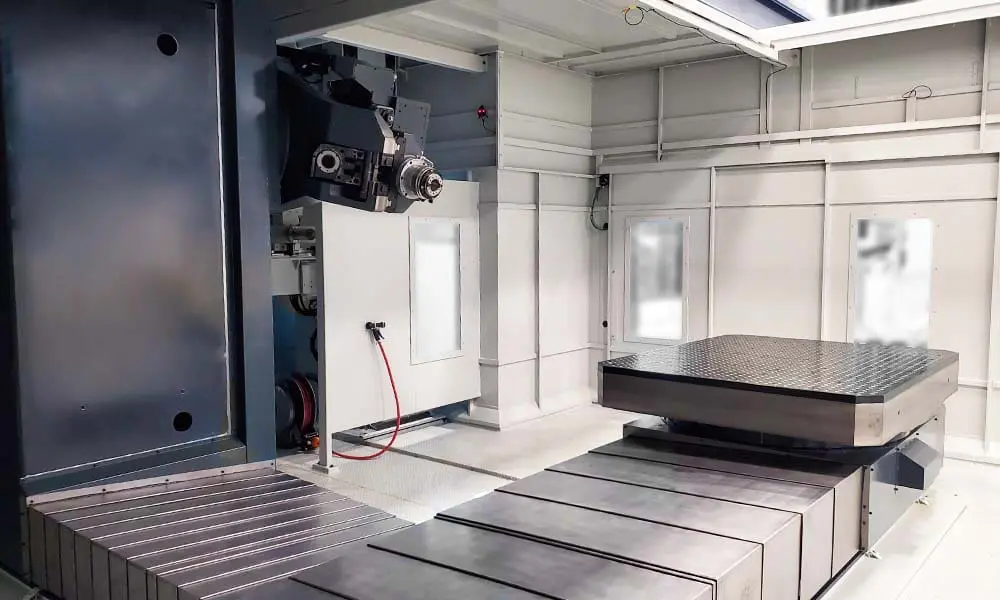

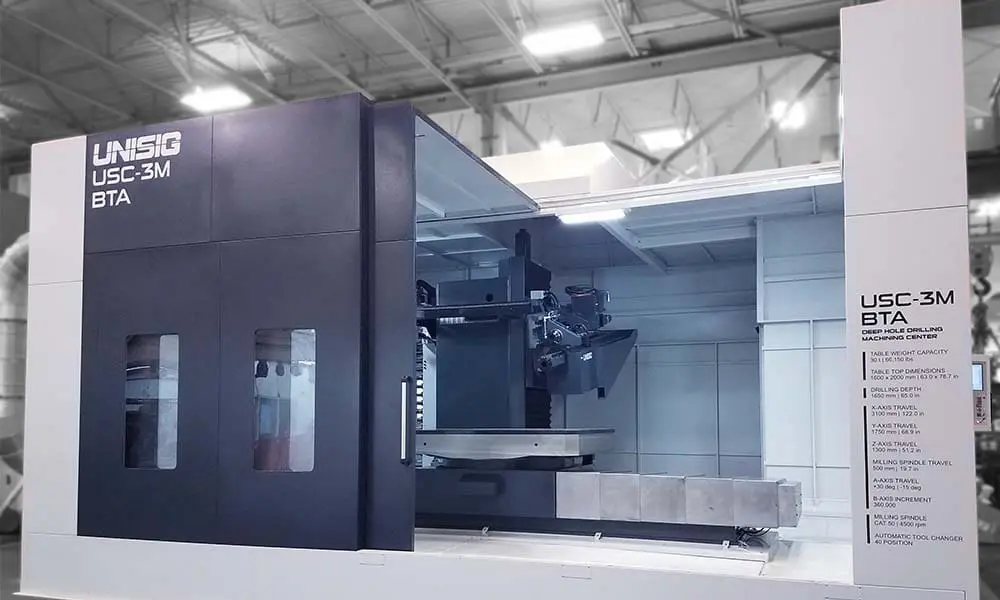

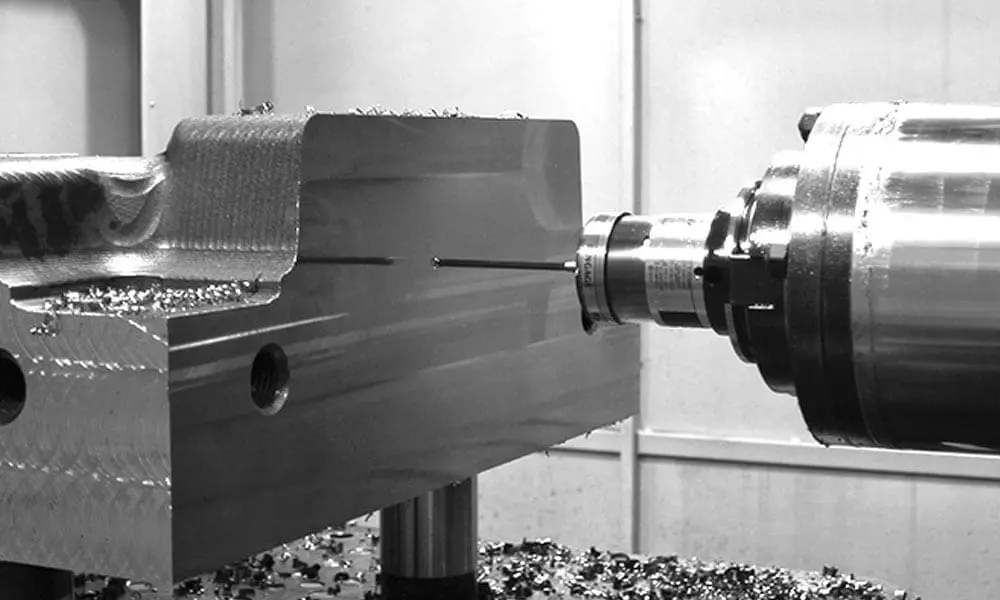

For manufacturers that have an opportunity to benefit from the combination of deep hole drilling and milling operations, UNISIG offers the USC-M series. Machines maximize production by allowing the fastest deep hole drilling with milling, with 5-axis positioning, to perform a range of complex machining in a single machine and setup.

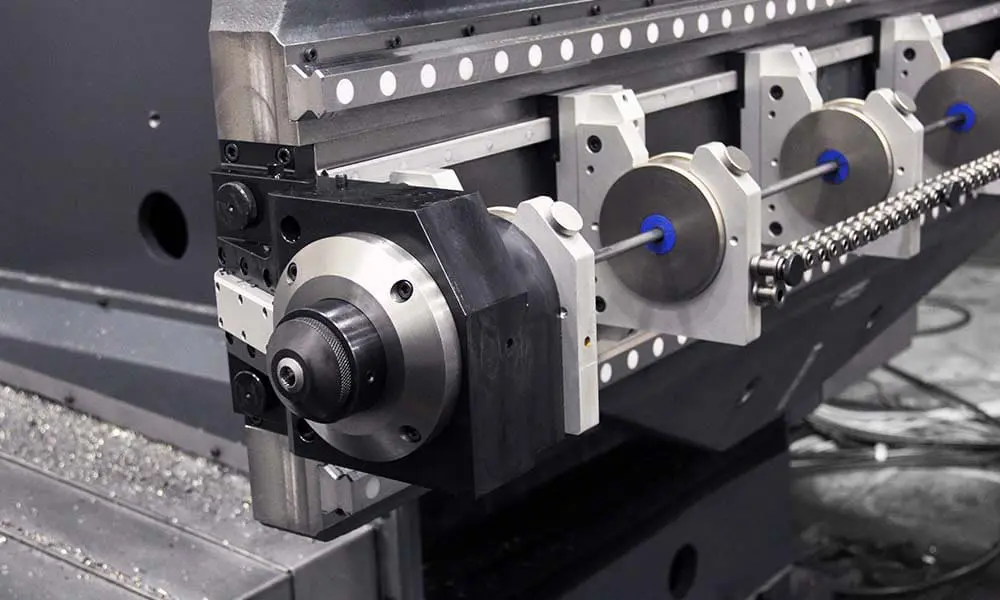

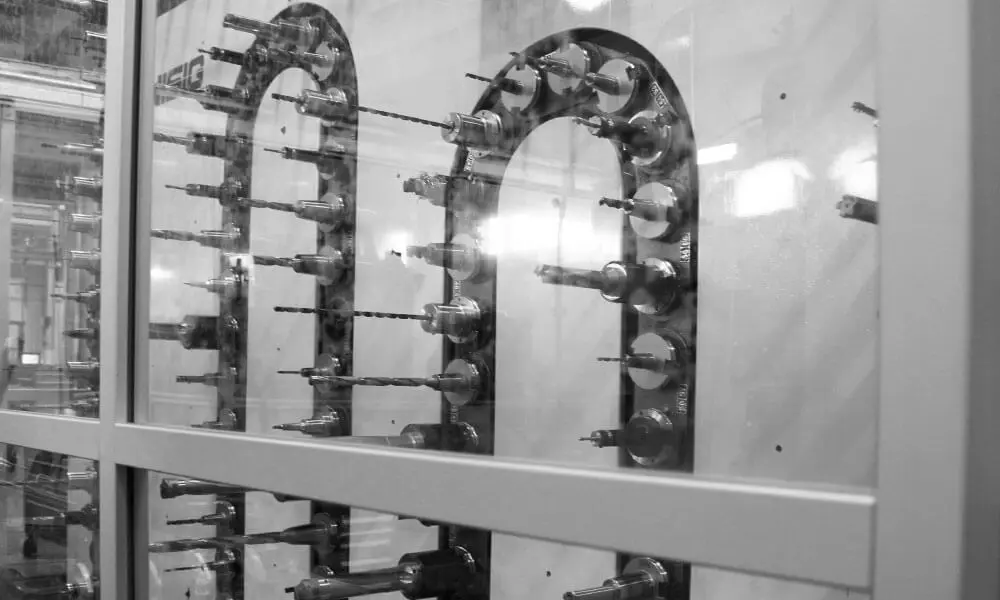

USC-M series machines offer a full range of solutions for manufacturers, including heavy weight table capacities, a rotating A-axis, automatic tool changers, and intuitive controls on each machine. Models are available in a range of capacities and options, with engineered universal (gundrilling + machining) or dedicated (deep hole drilling, milling) spindles.

USC-M Machines are available in three base configurations to meet the full range of manufacturer needs.

Universal gundrilling + milling combination spindle with quick changeover for a range of operations in a single machine

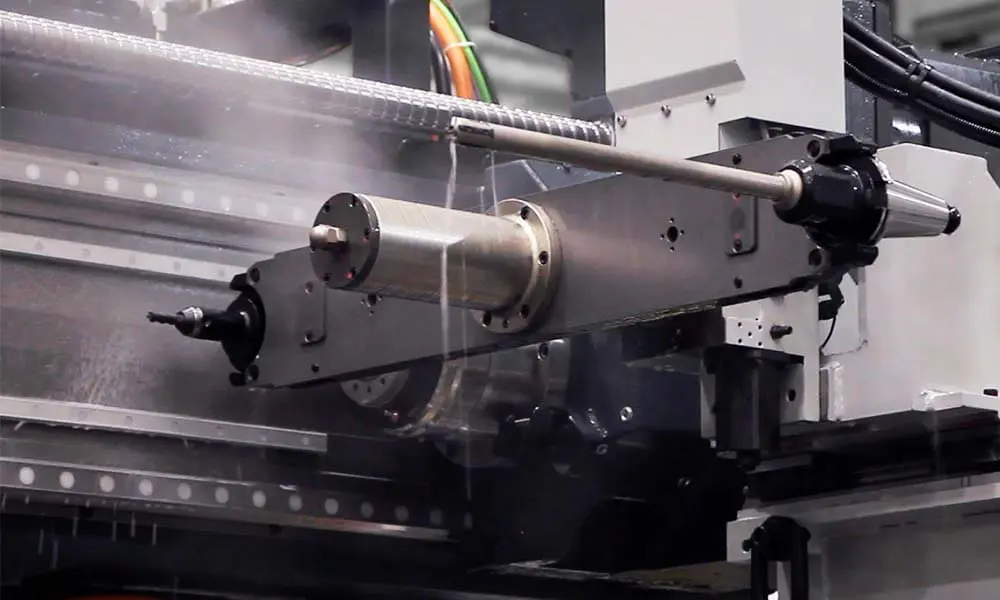

Dedicated spindles for BTA + gundrilling, and milling, for powerful machining capabilities and improved feed rates

Dedicated spindles for BTA + gundrilling, and milling, plus robust options for the ultimate in milling and drilling performance

| Description | USC-2M | USC-3M | USC-2M-BTA | USC-3M-BTA | USC-M38 | USC-M50 |

|---|---|---|---|---|---|---|

| PERFORMANCE | ||||||

| Spindle Type | Universal | Universal | Dedicated | Dedicated | Dedicated | Dedicated |

| Nominal drilling depth | 1,500 mm | 1,800 mm | 1,650 mm | 1,650 mm | 1,500 mm | 1,830 mm |

| Gundrilling diameter | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm |

| BTA Drilling Diameter | — | — | 38 mm | 38 mm | 38 mm | 50 mm |

| TRAVELS | ||||||

| X-Axis (horizontal) | 2,100 mm | 3,100 mm | 2,100 mm | 3,100 mm | 2,200 mm | 3,100 mm |

| Y-Axis (vertical) | 1,750 mm | 1,750 mm | 1,750 mm | 1,750 mm | 1,700 mm | 2,500 mm |

| Z-axis (horizontal) | 850 mm | 1,300 mm | 850 mm | 1,300 mm | 1,000 mm | 1,550 mm |

| A-Axis inclination | -30°, +15° | -30°, +15° | -30°, +15° | -30°, +15° | -30°, +15° | -30°, +20° |

| B-axis (rotary table) | 360,000 positions | 360,000 positions | 360,000 positions | 360,000 positions | 360,000 positions | 360,000 positions |

| Drilling or Universal spindle | 2,300 mm | 2,700 mm | 2,000 mm | 2,000 mm | 1,830 mm | 2,450 mm |

| Machining spindle | – | – | 500 mm | 500 mm | 500 mm | 500 mm |

| TABLE | ||||||

| Top surface | 1,250 x 1,600 mm | 1,600 x 2,000 mm | 1,250 x 1,600 mm | 1,600 x 2,000 mm | 1,000 x 1,200 mm | 1,250 x 1,600 mm |

| Table Weight Capacity | 20 t | 30 t | 20 t | 30 t | 15 t | 23 t |

| MACHINING SPINDLE | ||||||

| Spindle nose | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 |

| Maximum speed | 4,500 rpm | 4,500 rpm | 4,500 rpm | 4,500 rpm | 4,500 rpm (2-range, geared) | 4,500 rpm (2-range, geared) |

| Power (480V S1 100% / S6 60%) | 24 kW / 30 kW | 24 kW / 30 kW | 20 kW / 25 kW | 20 kW / 25 kW | 20 kW / 25 kW | 24/30 kW |

| DRILLING SPINDLE | ||||||

| Spindle nose | — | — | DHD | DHD | DHD | DHD |

| Maximum speed | — | — | 4,500 rpm | 4,500 rpm | 5,000 rpm | 5,000 rpm |

| Power (S1 100% / S6 60%) | — | — | 15 kW/ 20 kW | 15 kW/ 20 kW | 15 kW/ 20 kW | 24 kW/ 30 kW |

| TOOL CHANGER | ||||||

| Automatic Tool Changer | 60 position | 60 position | 40 position | 40 position | 120 position | 120 position |

| CONTROLS | ||||||

| CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC |

| Description | USC-2M | USC-3M | USC-2M-BTA | USC-3M-BTA | USC-M38 | USC-M50 |

|---|---|---|---|---|---|---|

| PERFORMANCE | ||||||

| Spindle Type | Universal | Universal | Dedicated | Dedicated | Dedicated | Dedicated |

| Nominal drilling depth | 59.1 in | 70.9 in | 65.0 in | 65.0 in | 59.1 in | 72.0 in |

| Gundrilling diameter | 2.0 in | 2.0 in | 2.0 in | 2.0 in | 2.0 in | 2.0 in |

| BTA Drilling Diameter | — | — | 1.5 in | 1.5 in | 1.5 in | 2.0 in |

| TRAVELS | ||||||

| X-Axis (horizontal) | 82.7 in | 122.0 in | 82.7 in | 122.0 in | 86.6 in | 122.0 in |

| Y-Axis (vertical) | 68.9 in | 68.9 in | 68.9 in | 68.9 in | 66.9 in | 98.4 in |

| Z-axis (horizontal) | 33.5 in | 51.2 in | 33.5 in | 51.2 in | 39.4 in | 61.0 in |

| A-Axis inclination | -30°, +15° | -30°, +15° | -30°, +15° | -30°, +15° | -30°, +15° | -30°, +20° |

| B-axis (rotary table) | 360,000 positions | 360,000 positions | 360,000 positions | 360,000 positions | 360,000 positions | 360,000 positions |

| Drilling or Universal spindle | 90.6 in | 106.3 in | 78.7 in | 78.7 in | 72.0 in | 96.5 in |

| Machining spindle | – | – | 19.7 in | 19.7 in | 19.7 in | 19.7 in |

| TABLE | ||||||

| Top surface | 49.2 x 63.0 in | 63.0 x 78.7 in | 49.2 x 63.0 in | 63.0 x 78.7 in | 39.4 x 47.2 in | 49.2 x 63.0 in |

| Table Weight Capacity | 44,100 lbs | 66,615 lbs | 44,100 lbs | 66,615 lbs | 33,069 lbs | 50,715 lbs |

| MACHINING SPINDLE | ||||||

| Spindle nose | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 | SK50/CAT 50 |

| Maximum speed | 4,500 rpm | 4,500 rpm | 4,500 rpm | 4,500 rpm | 4,000 rpm (2-range, geared) | 4,000 rpm (2-range, geared) |

| Power (480V S1 100% / S6 60%) | 32 hp / 40 hp | 32 hp / 40 hp | 27 hp / 34 hp | 27 hp / 34 hp | 27 hp / 34 hp | 32 hp / 40 hp |

| DRILLING SPINDLE | ||||||

| Spindle nose | — | — | DHD | DHD | DHD | DHD |

| Maximum speed | — | — | 4,500 rpm | 4,500 rpm | 5,000 rpm | 5,000 rpm |

| Power (S1 100% / S6 60%) | — | — | 20 hp/ 27 hp | 20 hp/ 27 hp | 20 hp/ 27 hp | 32 hp/ 40 hp |

| TOOL CHANGER | ||||||

| Automatic Tool Changer | 60 position | 60 position | 40 position | 40 position | 120 position | 120 position |

| CONTROLS | ||||||

| CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC | Heidenhain CNC |