Jul

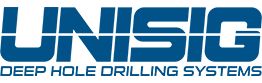

UNISIG UNX20-CP Off-Center Drilling Machine

- 2023

- Ampersand Milwaukee

UNX-CP machines from UNISIG are designed to meet the challenges of off-center holes with extreme depth to diameter ratios. Cartesian and Polar positioning [CP] are combined with advanced motion control to achieve the highest accuracy in small diameter deep hole drilling. Programmable off-center continuous counter-rotation improves hole concentricity, even at depth to diameter ratios of 375:1.