Service parts excellence begins with a strong commitment to inventory. UNISIG maintains more than three million dollars in parts on hand to reduce or eliminate wait times for critical components.

UNISIG Service Parts Excellence

- Posted on

- Ampersand Milwaukee

LIFETIME OF SUPPORT BACKED BY OPERATIONAL EXCELLENCE

UNISIG builds precision deep hole drilling machines and automation. These are high-value products that represent a significant investment for our customers. Our service and parts teams help customers keep their machines running at their best for the entire life of the machine, often 20 years or more. That is why we focus on making service parts available quickly and reliably, ensuring long-term performance and uptime.

Committed, Managed, and Integrated Inventory

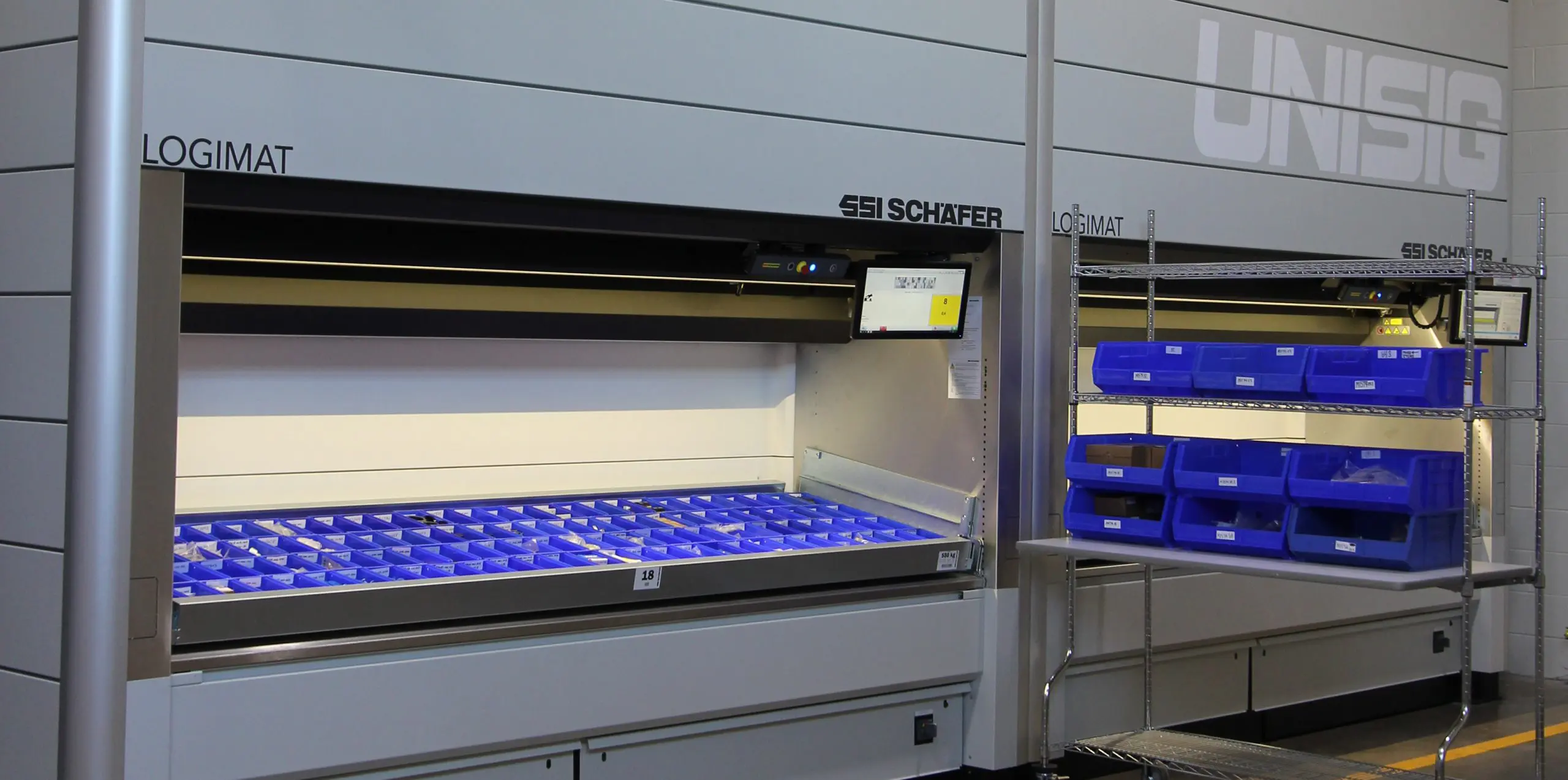

Smart Storage and Fast Delivery

Engineering Meets Operational Excellence

Frequently Asked Questions

UNISIG machines are designed for decades of performance, and our service and parts teams provide support for the entire life of the machine.

We maintain more than three million dollars in inventory and use advanced planning systems to actively manage stock levels, safety stock, and replenishment to minimize downtime.

Beyond precision machine design, we invest in infrastructure, including inventory, planning, and logistics. This ensures every customer receives reliable long-term support and dependable service.