Nov

WHAT DOES IT MEAN TO BUILD AUTOMATION?

- 2025

- Ampersand Milwaukee

Automation is part of our DNA at UNISIG. Many of our deep hole drilling machine projects include some level of automation, and we think about it at every step of development. This approach allows us to offer customers automation options with their initial purchase or as a future upgrade, ensuring their investment is compatible with automated production.

UNISIG machines are servo-driven and equipped with programmable feed rates, positions, and spindle speeds that optimize production. Many models also include servo-driven workpiece positioning systems that automatically prepare the machine for the next part. The user interface clearly shows the machine’s position and cycle status, making it simple for operators to complete one cycle and start the next.

Before automating a machine, the drilling operation itself must be stable and controlled. UNISIG’s process monitoring system tracks drilling conditions in real time and can automatically adjust parameters to maintain cycle performance. When limits are reached, the machine interrupts operation to protect the tool and workpiece while communicating what fault caused the stoppage. This feedback helps operators fine-tune parameters for successful drilling and establish tool life settings for high-volume production.

INTEGRATED AUTOMATION: BUILT FOR EFFICIENCY

“Automation is never an afterthought. It is built in from the very beginning.”

INTEGRATED AUTOMATION: BUILT FOR EFFICIENCY

“Automation is never an afterthought. It is built in from the very beginning.”

READY-ENGINEERED SYSTEMS: PROVEN AND SCALABLE

ADVANCED EXPERTISE: SIMPLE UPGRADES TO COMPLEX CELLS

READY-ENGINEERED SYSTEMS: PROVEN AND SCALABLE

ADVANCED EXPERTISE: SIMPLE UPGRADES TO COMPLEX CELLS

FREQUENTLY ASKED QUESTIONS

UNISIG offers a range of automation options, including in-machine conveyors, pallet systems, bulk feeders, robot integration, and multi-machine automation cells managed by the UNISIG Automation Cell Controller (ACC).

No. UNISIG provides ready-engineered and proven automation solutions. Our team guides customers through setup and operation to ensure a smooth transition into automated production.

Yes. Many UNISIG machines are designed to be automation-ready from the start, allowing customers to add automation systems as production needs grow.

Sep

UNISIG Service Parts Excellence

- 2025

- Ampersand Milwaukee

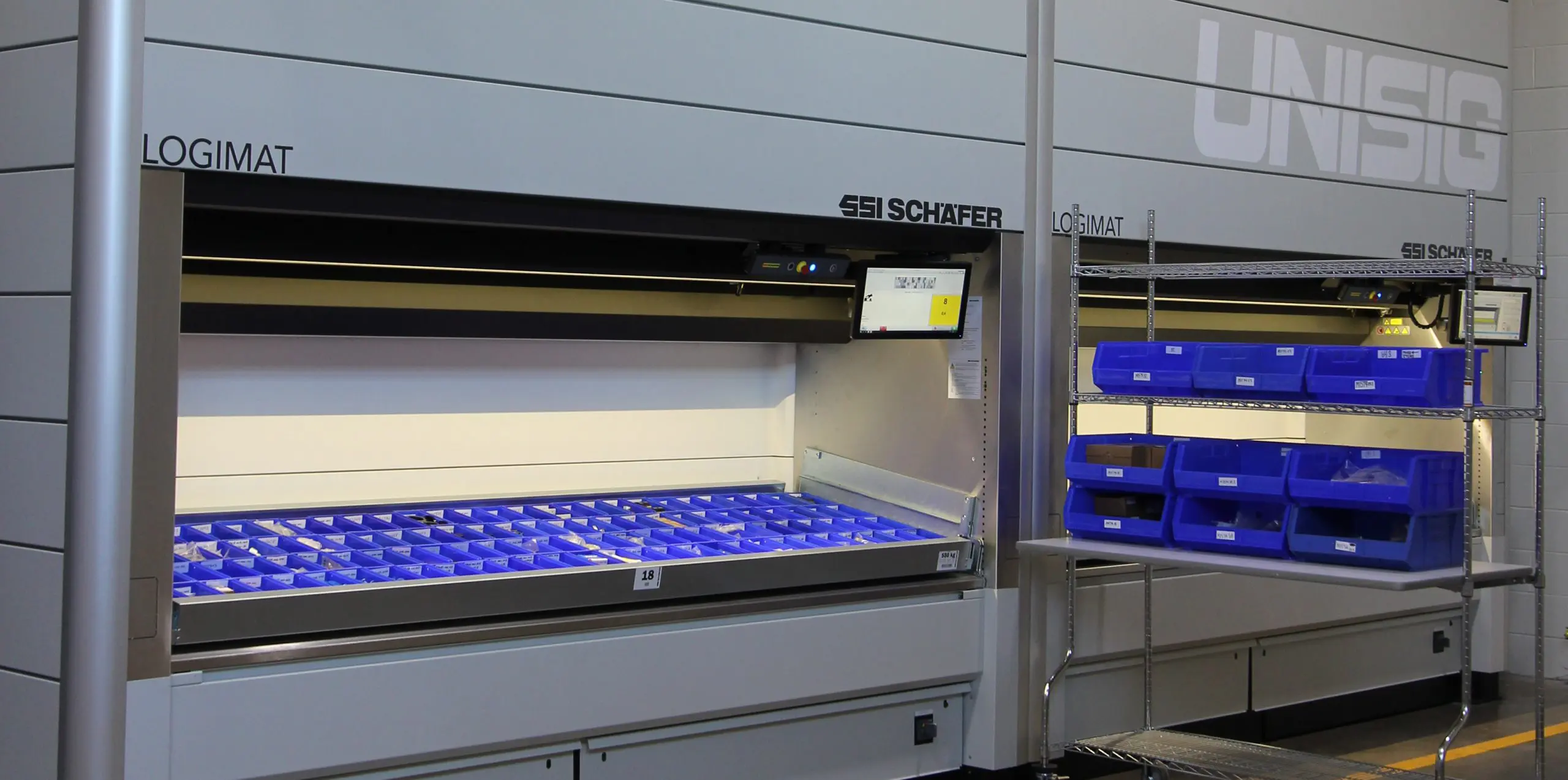

LIFETIME OF SUPPORT BACKED BY OPERATIONAL EXCELLENCE

UNISIG builds precision deep hole drilling machines and automation. These are high-value products that represent a significant investment for our customers. Our service and parts teams help customers keep their machines running at their best for the entire life of the machine, often 20 years or more. That is why we focus on making service parts available quickly and reliably, ensuring long-term performance and uptime.

Committed, Managed, and Integrated Inventory

Smart Storage and Fast Delivery

Engineering Meets Operational Excellence

Frequently Asked Questions

UNISIG machines are designed for decades of performance, and our service and parts teams provide support for the entire life of the machine.

We maintain more than three million dollars in inventory and use advanced planning systems to actively manage stock levels, safety stock, and replenishment to minimize downtime.

Beyond precision machine design, we invest in infrastructure, including inventory, planning, and logistics. This ensures every customer receives reliable long-term support and dependable service.

Sep

UNISIG Promotes Steve Landmann to Vice President of Sales

- 2025

- Ampersand Milwaukee

About UNISIG

UNISIG is a leading manufacturer of deep hole drilling machines and automation systems. Engineered and manufactured in the USA, its machines serve industries ranging from aerospace to medical to moldmaking. Known for engineering innovation and in-house manufacturing capabilities, UNISIG combines precision, performance, and reliability in everything it delivers. For more information, visit www.UNISIG.com

Steve Landmann has been promoted to Vice President of Sales at UNISIG. He has over a decade of experience managing the Midwest sales region, where he contributed significantly to strengthening UNISIG’s reputation for delivering robust, customer-focused solutions. In his new role, he will lead the global sales team and work closely with management to anticipate evolving customer needs and reinforce the company’s leadership in deep hole drilling solutions.

Landmann brings a unique perspective shaped by his experience in predictive maintenance, machine building, and installation. This hands-on background gives him a deep understanding of customer challenges and long-term needs, positioning him to continue UNISIG’s tradition of solution-driven selling in high-value equipment markets.

Landmann succeeds Jeff Price, who is retiring in December after more than 22 years as Vice President of Sales. Price played a pivotal role in UNISIG’s global footprint and long-term growth. This transition ensures continuity while also advancing UNISIG’s customer-focused strategy under new leadership.

Jul

How Laser Welding is Changing Fabrication

- 2025

- Ampersand Milwaukee

ADVANCING FABRICATION WITH LASER WELDING

UNISIG designs and builds deep hole drilling machines and automation systems. We provide the latest tools, equipment, and technology so our skilled team can take pride in their work and enjoy producing high-precision machines. One of those tools is our hand-held laser welder. We fabricate machine enclosures and other components that require long, watertight, clean welds. Our team of welders has used the latest MIG and TIG welding technologies to deliver high-quality results. When laser welding became viable, we saw its potential, but it took planning and preparation to bring it online.

Better Welds, Faster

Why it Matters

Frequently Asked Questions

Laser welding lets us produce cleaner, stronger, and watertight welds faster and with less finishing work. This boosts precision, reduces costs, and expands what’s possible in machine design. Our customers benefit from higher quality and faster delivery of machines.

We continue to use MIG welding for heavy plates and TIG welding for detailed tasks. Laser welding adds a new level of speed and quality, especially watertight welds along full panels without heat distortion.

Jul

BTA Drilling: Brazed Versus Indexable Tooling

- 2023

- Ampersand Milwaukee

Deep hole drilling applications can be approached in several ways, but one of the most effective methods is often BTA drilling. BTA stands for Boring and Trepanning Association, although it is sometimes referred to as STS or Single Tube System drilling. Unlike gun drills or twist drills a BTA drill features internal chip removal, which has advantages in both productivity and hole quality.

The BTA drill head has multiple carbide cutting edges and guide pads mounted to it. Open spaces are designed into the head for chip removal, and chips are evacuated through the drill tube the head is threaded onto. Pressurized coolant surrounds the drill head in operation, and is key to forcing chips through the head and out the drill tube. This method of chip evacuation allows for a very clean and reliable process with excellent surface finish and high drill feed rates – typically 5-7 times faster than gundrilling at the same diameter. No peck cycles or feed interruptions are needed, resulting in reduced machine time while drilling extended depth-to-diameter ratios even greater than 40:1.

The BTA drill head has multiple carbide cutting edges and guide pads mounted to it. Open spaces are designed into the head for chip removal, and chips are evacuated through the drill tube the head is threaded onto. Pressurized coolant surrounds the drill head in operation, and is key to forcing chips through the head and out the drill tube. This method of chip evacuation allows for a very clean and reliable process with excellent surface finish and high drill feed rates – typically 5-7 times faster than gundrilling at the same diameter. No peck cycles or feed interruptions are needed, resulting in reduced machine time while drilling extended depth-to-diameter ratios even greater than 40:1.

BTA drills are generally available in two forms: brazed or indexable; and tool selection is dependent upon several factors. As the name implies, brazed tools involve brazing a carbide insert and guide pads onto a steel body, while indexable BTA drilling tools have carbide inserts either directly mounted to the head with a retention screw or seated in a cartridge that is mounted to the tool.

Hole diameter is the initial consideration when determining whether to use brazed or indexable BTA drills. For small hole diameters – generally 12 to 20 mm in diameter – brazed tools are often the first choice as it’s difficult to make small inserts and screws strong enough to withstand the torque and forces of BTA drilling. (Manufacturers of BTA drilling tools continue to make improvements in indexable BTA heads as small as 8 mm in diameter, however).

Brazed tools offer extremely close tolerances and excellent surface finish as the insert and guide pads are mounted and then ground to the specified diameter, providing almost perfect concentricity and cylindricity. Ease of use is also a benefit – simply attach the head to the drill tube and discard it when it has dulled or failed. If you experience a tool failure, the investment in drill head isn’t as costly as repairing or replacing an indexable drill head. Finally, an indexable BTA head can only be as accurate as the tolerance of the inserts themselves; but a brazed head has been ground to a very precise tolerance from the manufacturer.

By contrast, hole diameters starting at approximately 20 mm favor indexable tools, primarily for economic reasons. Replacing larger diameter brazed tools is expensive, whereas indexing an insert and guide pads gives an easy extension on the tool’s life. Indexable insert manufacturers also offer an exhaustive range of carbide grades, coatings and chip breakers for application-specific advantages.

The placement of the indexable inserts on BTA drill head varies by diameter and by manufacturer, and can include one or multiple inserts mounted directly to the head or set in a heat-treated cartridge which is then mounted to the head. Guide pads are typically mounted the head to counter the drilling forces and burnish the hole during drilling. Indexing, or rotating, a direct-mounted insert is as simple as loosening the retaining screw and turning the insert to expose a fresh cutting edge. If the insert and pocket were made with tight tolerances, your cutting diameter should remain reasonably consistent.

Cartridge-mounted inserts, however, typically incorporate a shim or other adjustment system to allow for a much more precise diameter setting after indexing inserts and guide pads. This process does require additional equipment, however, such as a micrometer and stand or tool presetter – as well as the skills needed to accurately make the necessary adjustments.

Whether you select brazed or indexable BTA drills for your deep hole drilling application, you will be rewarded with high feed rates and process reliability, along with minimal centerline deviation and excellent hole quality.

To learn more, contact UNISIG about its complete portfolio of BTA drilling machines, drill tubes, tools and BTA durable tooling.