Jul

The benefits of vibration dampening technology in BTA deep hole drilling

- 2023

- Matt Zimmerman

![]() UNISIG B-Series deep hole drilling machines are capable of drilling to depths of 100 x diameter or greater. But with BTA drill tubes as long as 30 feet spinning at high RPMs, vibration is an inevitable side-effect which can derail the hole concentricity and degrade the surface finish – or worse. This is routinely combatted through the use of vibration dampeners, installed at intervals along the length of the drill tube, to support the tube during drilling and reduce the effect of harmonic resonance or vibration.

UNISIG B-Series deep hole drilling machines are capable of drilling to depths of 100 x diameter or greater. But with BTA drill tubes as long as 30 feet spinning at high RPMs, vibration is an inevitable side-effect which can derail the hole concentricity and degrade the surface finish – or worse. This is routinely combatted through the use of vibration dampeners, installed at intervals along the length of the drill tube, to support the tube during drilling and reduce the effect of harmonic resonance or vibration.

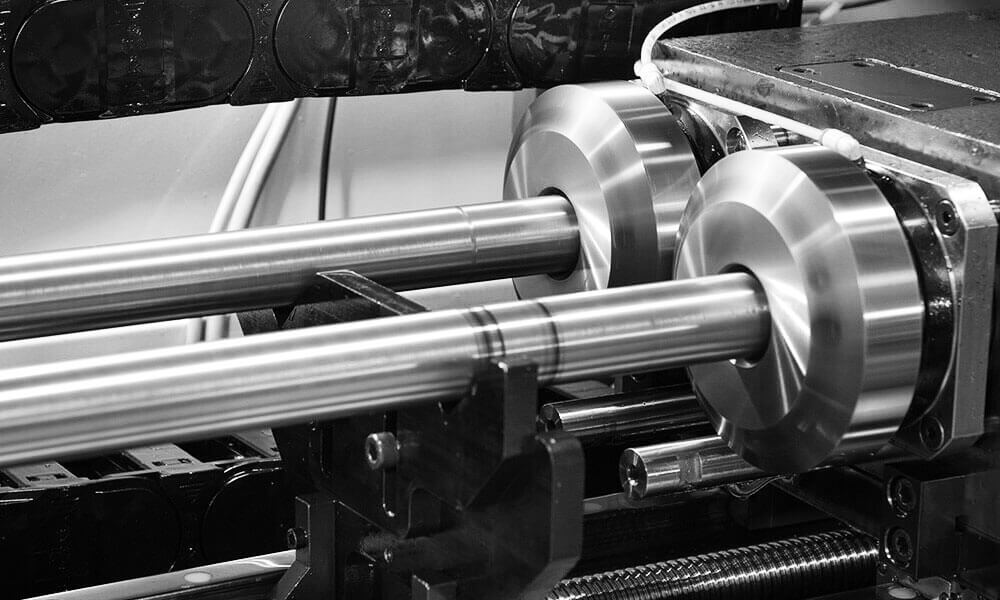

Vibration dampening assemblies are comprised of heat treated components and precision bearings that clamp around the BTA drill tube (see durable tooling on website). Standard vibration dampeners are manually adjusted prior to drilling via tensioning locknuts on each end of a tapered collet, for a durable and cost-effective solution.

Hydraulic vibration dampeners offer the ability to adjust the dampening effect on the drill tube during drilling operations with an internal hydraulic piston. These dampeners, although a more complex system with a higher price point, offer multiple advantages over standard dampening assemblies:

- Micro-adjustments to the clamping pressure are possible with hydraulic vibration dampeners, with finer control ability than the adjusting threads of a traditional dampener allow.

- Repeatable clamping set points can be achieved, as the pressure gauge provides a readout to allow the documentation of set points for future setups.

- Hydraulic vibration dampeners allow you to adjust the clamping pressure – or release – during the drilling operation. This is extremely helpful in deep-hole drilling operations because harmonics tend to change at different depth-to-diameter ratios, and workpiece material may have hard spots that change the vibration characteristics mid-operation. When multiple dampening devices are being used, this system also allows the release of pressure from individual dampeners when they are no longer needed.

- No hand tools are needed to adjust the clamping pressure, allowing the operator to make adjustments quickly and easily.

Hydraulic vibration dampeners can be controlled with a manual screw pump or powered hydraulic unit. A manual pump is a lower-cost system, while still offering all the advantages listed above. For an improved ability to control and adjust the pressure on the drill tube, the dampening assemblies can be actuated by a central hydraulic unit. This allows the operator to make changes at the machine control, and pressure settings can become part of the program on CNC-equipped machines. This is the highest level of control – and repeatability – in vibration dampening technology that UNISIG has installed on B-Series deep hole drilling machines.

B-Series BTA Machines, < 800mm Swing | B-Series BTA Machines, > 800mm Swing

The shop’s recently added automated gundrilling process simplifies completion of large orders with long delivery schedules. Most of the shop’s workflow involves long-term contracts and multi-month purchase orders for 1,000 or more parts. That streamlined workflow thanks to automation makes production planning easy because the company can establish shipping dates and work backward to create the build schedule.

The shop’s recently added automated gundrilling process simplifies completion of large orders with long delivery schedules. Most of the shop’s workflow involves long-term contracts and multi-month purchase orders for 1,000 or more parts. That streamlined workflow thanks to automation makes production planning easy because the company can establish shipping dates and work backward to create the build schedule.