Gun drilling is a precision deep hole drilling process that uses a long, straight tool to produce extremely deep holes in a variety of materials. This tool has a unique head geometry, and a groove along the length of the tool, differentiating it from a conventional twist drill.

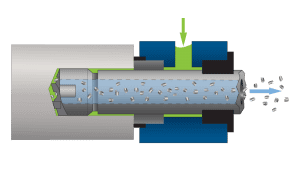

A gun drill cuts with coolant that is introduced through a hole in the tool, and exhausts chips through the groove. Additionally, guide pads on the tool head work to burnish the hole while drilling, resulting in an extremely round hole with a precision diameter. This internal coolant/external exhaust feature distinguishes gun drilling from other deep hole drilling methods.

Gun drilling developed out of a need to drill gun barrels. Before this process was developed, barrels were created with a strip of metal that was wrapped and welded around a mandrel, creating a weapon that was less straight, and less strong, than modern guns. Eventually, the drilling process was applied in order to create the part of a solid piece of metal. However, the original twist drills that were used required multiple passes, and resulted in less round, less straight holes.

Gun drilling is a method that eliminates both of these issues. As the gun drilling process improved, and equipment was developed for these tools, it proved beneficial for a variety of industries beyond guns and armaments. The small, deep, precise holes made possible by gun drilling are also used for energy applications, automotive, aerospace, mold, and others. As global technology continues to develop, additional applications are added to this list.

Pertinent Features

Modern gun drill tools are manufactured out of solid carbide, brazed and indexable, and do not require an additional drill tube. The non-cutting end of the tool has a driver, which is produced in standard sizes for use in gun drilling machines.

Coolant is often applied through a single round hole, but drills will also have multiple holes or kidney shaped holes to allow increased coolant flow. The v-shaped groove is designed to allow coolant to flush out chips cleanly and efficiently; this feature also generated the alternative name, single-fluted drill.

Gun drills have specific geometries, which have been determined to have the best cutting power, accuracy, and efficiency with chip creation and discharge. Variances in tool profiles include peripheral and nose grind geometry, coolant hole shape, head length, and guide pad shape and placement. Tools are chosen based on workpiece material and tolerance requirements. Many standard gun drill geometries have been tested to determine ideal specifications, and custom tools are commonly available as well.

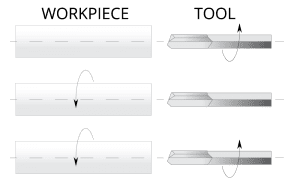

The process is idea when the required hole is less than 50 to 75 mm in diameter, and when the depth to diameter (D:d) ratio is 20:1 or greater. It is capable of maintaining accuracy to extreme ratios of up to 400:1. The process can be performed in three manners: rotating tool, stationary workpiece; rotating workpiece, stationary tool; or counter-rotating tool and workpiece. The latter is preferred for closer tolerances, and can achieve straightness up to 0.08 mm/m, and a surface finish of 0.2 µ-m Ra. Holes larger than this may be drilled with alternative deep hole drilling methods, and secondary machining processes can further contribute to roundness, straightness, and surface finish.

Why Use It?

Compared to other drilling methods, gun drilling offers several advantages, as well as cost and time-saving attributes. As mentioned, a gun drill is able to create a deep and accurate hole in a single pass. The use of guide pads as a burnishing tool also contributes to surface finish and often eliminates secondary finishing operations. The process is also the preferred method when precise roundness or straightness tolerances are required, or the workpiece metal is of a harder nature, as this method is capable of accuracy that twist drills cannot reach. Additionally, gun drill tips may be re-ground as they wear which can greatly increase tool life.

The process of gun drilling for these deep holes with extreme D:d ratios can benefit shops that drill either occasional deep holes, or utilize it in a production process. The increased efficiency and reduced error rates can add long-term value to a factory, and increase their capabilities with an additional specialized metal cutting process.

Deployment

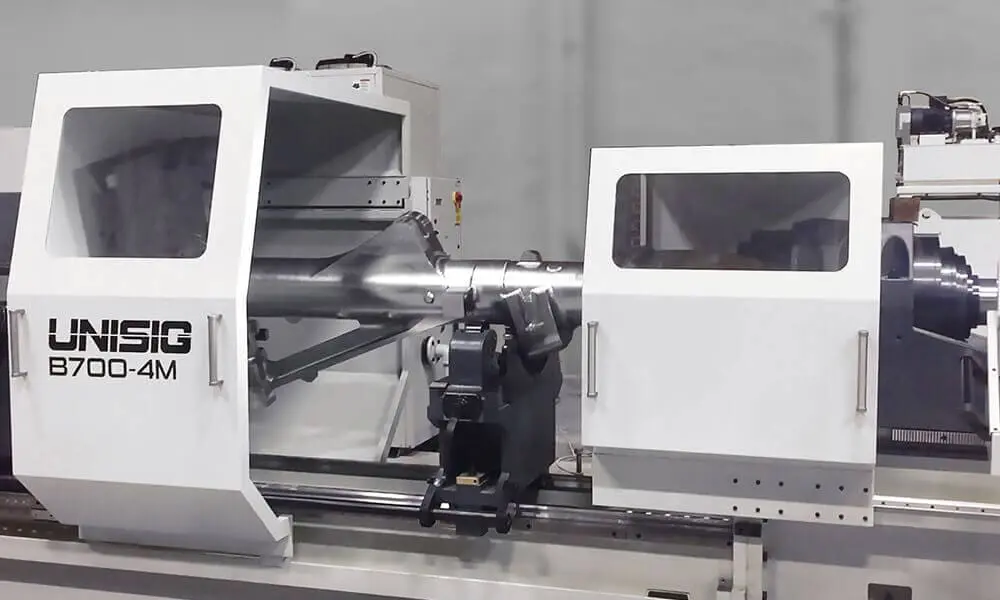

Gun drilling can be added in two ways: by retrofitting an existing machine for deep hole gun drilling, or with a deep hole gun drilling machine. Retrofitting for gun drilling is only effective up to a 10:1 drilling ratio, and generally in more common materials. Deeper holes or tougher materials may have their accuracy compromised with this method.

A deep hole drilling machine with gun drilling capabilities is better suited for more extreme holes and harder materials. Machines are engineered to reduce drift and enhance the straightness of the drill, reduce potential vibrations throughout the length of the tool, ensure clean and accurate entry and exit holes, and incorporate a coolant system for efficient drilling and chip exhaust.

Additionally, gun drilling machines provide benefits of process integration and monitoring, allowing operators to efficiently drill holes with high efficiency and close control over the drilling process.

A drill bushing makes contact with the workpiece, centering the entrance point and sealing the surface. Directly behind the bushing is a chip box, which contains the externally exhausted chips and coolant as they are deposited into a bin. At the drill exit point, a breakthrough seal exists to maintain accuracy and contain coolant as the drill finishes its hole. A superior machine will ensure that all of these elements function together to drill the most accurate hole with the least amount of effort. It will also be engineered with hole sizes, workpiece materials, and drill choices considered.

Going Deeper & Bigger

Gun drilling is the appropriate method for the parameters discussed. However, it is one method in a larger category of deep hole drilling. Other methods are employed for holes larger than 75 mm in diameter, and do the same extreme ratios as gun drilling.

Unlike gun drilling, other deep hole drilling methods introduce coolant externally, as it flows around the drill head; chips and coolant are then exhausted internally, through the tool connecting drill tube. BTA drilling is a common method, and a more efficient choice for larger holes.

Other bore finishing methods such as skiving and roller burnishing, bottle boring, and pull boring, can be performed in this same manner. Adding deep hole drilling or gun drilling to your shop can add additional value and increase precision drilling capabilities.