Until recently, several types of tooling for deep-hole-drilling operations were considered specialty tools—ones that few cutting tool OEMs offered and even fewer actually supported. Today, many of those tools, such as indexable–insert tools for gundrills, are now readily available as standards and come with effective application support. All of which allows shops to easily implement such tooling and reap the deep-hole-drilling benefits of doing so.

Indexable-insert tooling triples drilling feed rates over those of conventional tools to maximize output. However, to actually run these tools to their full potential, deep-hole-drilling systems must now also generate three times as much power, torque and thrust as well as have the rigidity and stiffness to prevent any vibration.Fortunately though, the higher feed rates of indexable-insert tooling translates into increased output per spindle on deep-hole-drilling machines. That is, a machine using these innovative tools can drill the same number of parts—maintain a certain level of output—but with half the amount of spindles. Consider a production output level that would require 12 to 16 deep-hole-drilling spindles equipped with conventional tools. Indexable-insert tooling allows a shop to achieve that same level of output with only four spindles.

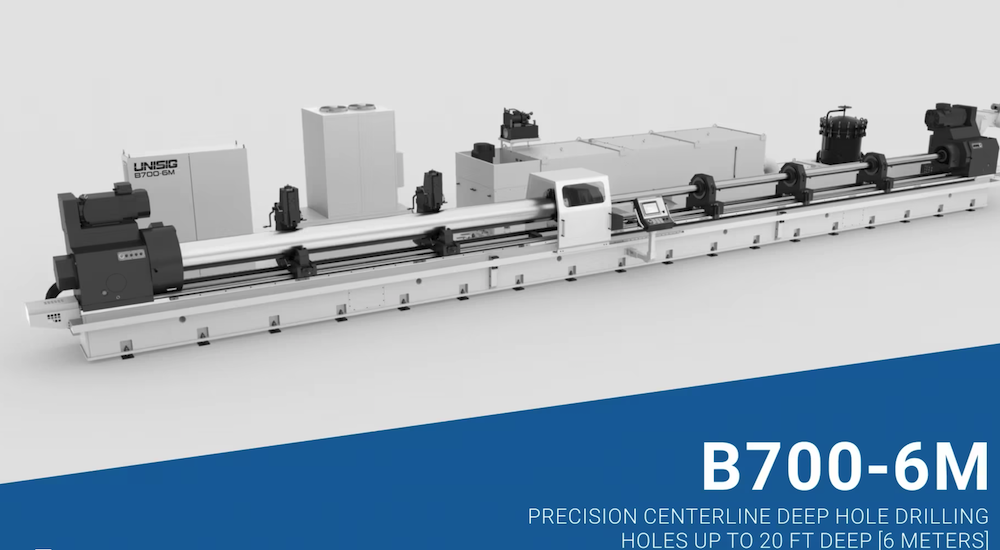

Such productive dedicated deep hole drilling systems mean that process planners/engineers can rethink their production cell layouts for improved cost-effectiveness without sacrificing output. Four-spindle gundrill machines, for example, take up approximately the same footprint as a large lathe. So, instead of four lathes, a shop can put in one gundrill machine and save 75% of the space while still getting the same level of output.

Highly productive gundrills need automation for maximized efficiency—not only external automation but internal automation as well. On its own, a single external robot is unable to load enough parts to keep all four spindles running. Instead, the external robot, or an operator, feeds parts to an internal loader inside the gundrill that then moves parts throughout the machine. This internal integral loader is an indexing “smart” conveyor that distributes the parts where needed.

Deep-hole-drilling process control and tool life management is even more critical for the high-performance machines that run indexable-insert drills, not only to keep operations running smoothly, but also to stop the process in the event of a problem before tool damage occurs. So those deep-hole-drilling system OEMs, such as UNISIG, that have always incorporated, in one form or another, process control and tool life management systems into their deep-hole-drilling technologies are now leaps and bounds ahead of those that have failed to do so.

Advancements in automation combined with the process control capabilities of deep-hole-drilling systems streamline their incorporation into production cells alongside conventional machining centers and other systems.

While it’s possible to perform certain deep-hole-drilling operations on machining centers and even be relatively productive, the deeper the required hole, the more the operation mechanically taxes the machine tool and diminishes its output. All of which leads to increased maintenance and higher tool expenditures.

This strategy also forces shops to add more machining centers to keep pace in the event of any surges in production demand. Conversely, the alternative is to instead integrate a deep-hole-rilling system that would relieve the machining centers of that operation. The cell’s robot could move parts from the machining centers to the deep-hole-drilling system.

Today’s deep-hole -rilling machine OEMs must always stay ahead of the curve in terms of tooling, then modify and engineer their machines accordingly to capitalize on any new technology. Doing so ensures that deep-hole-drilling systems continue to grow in capability and in application versatility to give shops further incentive to rethink the deep-hole-drilling process and how it could benefit their production operations.