Trepanning is a process used to create a hole in a workpiece by machining only the outer area of the hole, leaving an unmachined core in the center. A BTA drill creates the same hole by turning all of the material into chips, leaving no core behind. This gives manufacturers two distinct ways to create a hole from solid material.

WHEN IS TREPANNING THE RIGHT CHOICE?

- Posted on

- Ampersand Milwaukee

Trepanning is a process that creates a hole in a workpiece by machining only the outer area of the hole, leaving an unmachined core in the center. In contrast, a BTA drill creates the same hole by turning all of the material into chips, leaving no core behind. This provides manufacturers with two distinct ways to create a hole from solid material.

BTA drilling is simple in concept: set up the machine, drill the hole, remove the workpiece, and empty the chip hopper when it’s full. Many manufacturers choose this process for its straightforward operation and the convenience of chip recycling. Trepanning isn’t necessarily more difficult, but it requires more operator involvement. When the hole is complete, the retained core must be removed from the tool between cycles.

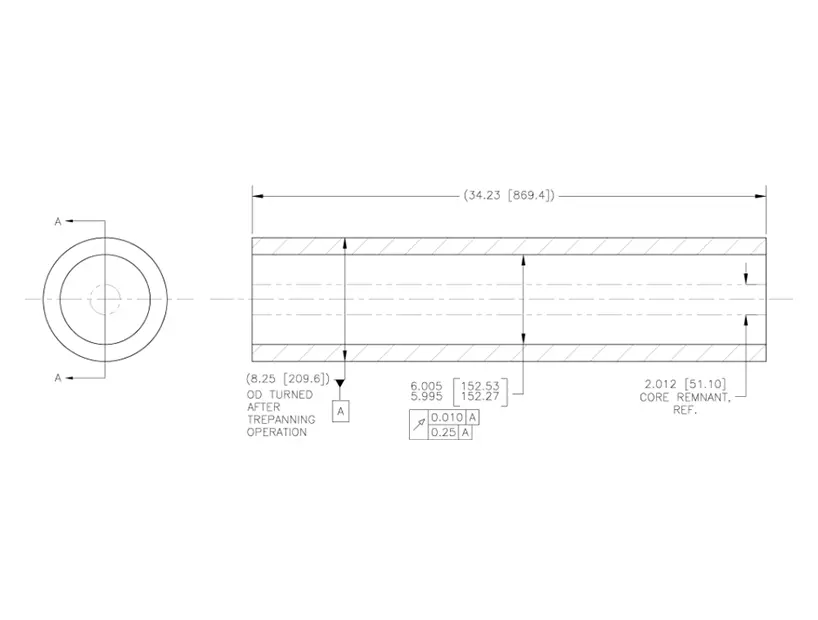

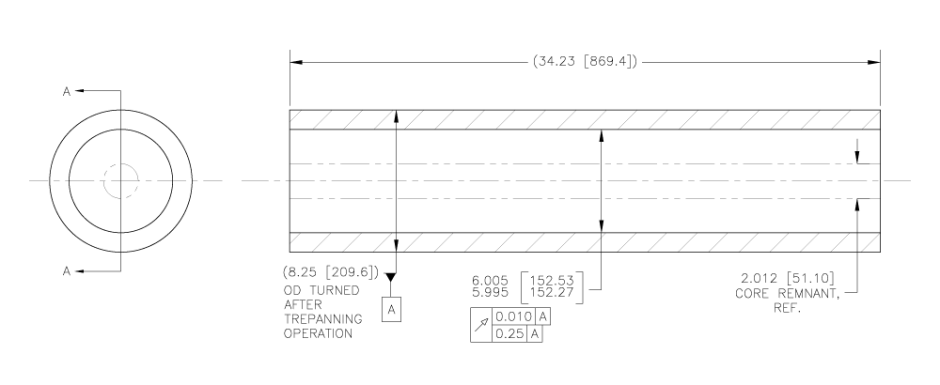

Trepanning and BTA solid drilling share the same coolant delivery and chip evacuation systems. Coolant is introduced around the outside of the tool, and chips are exhausted through the drill tube. In BTA drilling, coolant passes freely through the tube, carrying chips to the conveyor. In trepanning, however, chips taken by the coolant must pass by the workpiece core inside the tube. The bore quality between the two methods can be similar, but it depends on the tool design. Trepanning tools with a sufficient cutting width to engage guide pads can achieve diameter tolerances similar to solid drilling. Tools designed for the narrowest width of cut (leaving the largest core) generally produce lower bore quality. For very deep holes, a counter-rotating tool and workpiece are often used. Because the trepanning core rotates with the workpiece, it can create challenges related to vibration or unexpected loading. Once these differences are understood, the key question becomes: When is trepanning the right choice?

ADVANTAGES OF TREPANNING

ADVANTAGES OF TREPANNING

“Trepanning is not just an alternative to BTA drilling—it’s a strategic choice when core recovery, power efficiency, or tooling economy align with production goals.”

LIMITATIONS AND CONSIDERATIONS

EQUIPMENT FOR TREPANNING

LIMITATIONS AND CONSIDERATIONS

EQUIPMENT FOR TREPANNING

FREQUENTLY ASKED QUESTIONS

Trepanning is ideal when core recovery or reduced tooling cost is valuable, or when material properties must be preserved for testing or reuse.

It’s possible, but challenging. Specialized core-breaking or cropping tools are required to separate the core, which adds time and complexity.

Machines must be powerful, and designed for core handling. UNISIG B-Series machines can perform both trepanning and BTA drilling, offering flexibility for different applications.