Picture yourself facing knee surgery, under the care of a skilled orthopedic surgeon. Precision instruments, state-of-the-art monitoring equipment, and decades of experience

How to Drill Straighter: Concentricity in Deep Hole Drilling

- Posted on

- Anthony Fettig

Picture yourself facing knee surgery, under the care of a skilled orthopedic surgeon. Precision instruments, state-of-the-art monitoring equipment, and decades of experience are on hand, as they conduct a procedure that will ideally lead to more days on the court. The surgical team works patiently and carefully towards a successful outcome, relying on tools to guide their movements with exact precision, placing instruments exactly where they need to be in the body, and not even a half millimeter off. For deep holes in components to be accurate – including surgical tooling – they need to uphold tight concentricity tolerances, and in gundrilling, this happens best with counter-rotation. For a manufacturer, this is vitally important. For an end user, or in this case a patient facing surgery, it can make all the difference.

These precision parts are one of several applications that have deep holes, where concentricity is critical to the function of the part. Concentricity tolerances are achieved when the hole follows the desired axis of the part, eliminating drift from the point of entrance to the exit. In a round part with on-center drilling, this is easily illustrated; some applications may include deep holes which are off-center, or in non-round parts, but still have tight concentricity requirements.

These precision parts are one of several applications that have deep holes, where concentricity is critical to the function of the part. Concentricity tolerances are achieved when the hole follows the desired axis of the part, eliminating drift from the point of entrance to the exit. In a round part with on-center drilling, this is easily illustrated; some applications may include deep holes which are off-center, or in non-round parts, but still have tight concentricity requirements.

Low concentricity in some applications can result in parts with weak sidewalls, mismatched holes, or even scrapped parts. In other cases, manufacturers may decline production of these components, because of perceived impossibility or unproductiveness. With the addition of a counter-rotating process on deep hole drilling equipment, critical concentricity tolerances can become both achievable and economical.

How Counter-Rotation Improves Concentricity

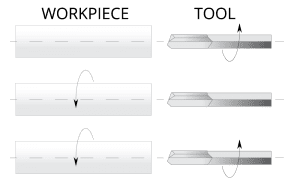

Drilling a deep hole is commonly achieved by rotating the cutting surface of a tool against the metal of a workpiece with two opposing spindles in a horizontal setup. Typically, this consists of a stationary workpiece and rotating tool, but can also be configured with a rotating workpiece and stationary tool, or a third option, with a counter-rotating tool and workpiece.

Common machining centers use a rotating cutting tool, such as a mill, and a fixtured, stationary workpiece. A lathe, alternatively, rotates a workpiece and cuts with a stationary tool. Much of the time, setups such as these are enough to achieve the goals and tolerances of a majority metal cutting tasks, but are limited when it comes to more extreme tolerances and depth-to-diameter ratios.

A tool-rotate configuration is the least accurate when it comes to concentricity. In this setup, gravity is believed to act on the base and shank of the tool, not the drilling tip, and along with the rotation of the tool. Because of the relative position of the tool and gravity to the workpiece, this configuration produces the poorest results. This tool-rotate process is common for shallower holes on a machining center, but as holes become deeper, and tolerances become tighter, this no longer works as a solution.

Workpiece-rotate-only setups produce holes that are approximately twice as concentric as tool-rotate. A rotating workpiece changes the relative force of gravity compared to the workpiece position, negating some of the effects on the finished hole. A rotating workpiece can be done on a lathe with limited capability, but is ideally performed on a dedicated deep hole drilling machine.

Counter rotating tool and workpiece improve significantly upon both of these, as the forces are never static – changing relative gravity and orientation will provide drilling conditions without a single constant net direction that the tool will follow. In this setup, the tool is restricted from drifting, and will produce a much more concentric finished hole.

Counter rotating tool and workpiece improve significantly upon both of these, as the forces are never static – changing relative gravity and orientation will provide drilling conditions without a single constant net direction that the tool will follow. In this setup, the tool is restricted from drifting, and will produce a much more concentric finished hole.

Counter-rotation is easily achievable with the right equipment and setup, whether it is for smaller gundrilled holes, or larger, longer BTA drilled components.

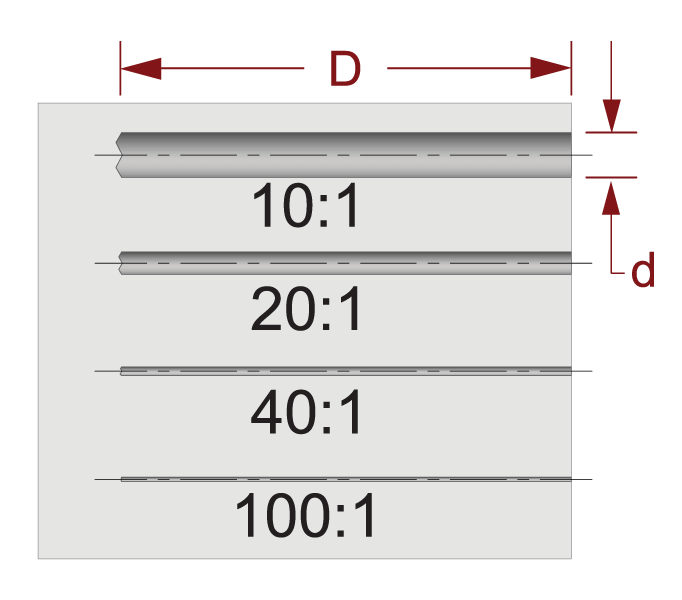

Deep holes are typically classified as anything with a depth-to-diameter (D:d) ratio of approximately 10:1 or greater, and can even reach extreme ratios of 100:1. As deep holes approach ratios of 20:1 or greater, drilling with specialty tooling on dedicated equipment is optimal. Modern deep hole drilling machines are designed to maximize the potential of tools such as gundrill and BTA processes.

The Data

To represent the impact of counter rotation, a test was performed on a 4140HT workpiece, 30 inches in length, ¾” outer diameter and a ¼” drilled hole. The depth to diameter (D:d) of this test is 120:1. This part is easily representative of a power transmission shaft or aerospace linkage.

Drilling these test workpieces produced the following results (measured using ultrasound):

- Rotating Tool, Stationary Work: 0.026 inch drift at 30 inches of drill length

- Stationary Tool, Rotating Work: 0.015 inch drift at 30 inches of drill length

- Rotating Tool, Counter Rotate Work: 0.009 inch drift at 30 inches of drill length

*results may vary based on material, depth-diameter ratio, tooling, etc.

Drilling holes with a 40:1 or less depth-diameter ratio can be done with limited drift using standard drilling practices. Beyond 40:1, counter-rotation really begins to deliver benefits with minimal drift.

Total Drift Comparison, Drilling Methods

Getting Started with Counter-Rotating Deep Hole Drilling

Typical machining centers are often not capable of deep holes greater than a 20:1 D:d ratio, and are not configured for counter-rotation. Rather, dedicated deep hole drilling machines are a superior consideration because they are designed specifically to manage accurate counter-rotation in gundrilling and BTA processes.

Deep hole drilling machines that enable successful counter-rotation include the right components, machined and assembled to maintain superior alignment. These range from the machine base, to rotating bearing groups and spindles, to tool and workpiece support – all of which uphold alignment and work as a system. This allows the machine to maintain accuracy while moving, and hold concentricity tolerances throughout the depth of the hole.

For deep hole machine builders, alignment considerations begin with the machine base. Each component is designed with alignment as a priority,as well as machining and environmental factors like temperature and gravity. Counter rotation may be possible on machines retrofitted with a second rotating group, but will often need to undergo an alignment improvement process which creates additional challenges. Equipment designed with this purpose will have the right combination of benefits to make concentricity tolerances manageable for nearly any operator.

For deep hole machine builders, alignment considerations begin with the machine base. Each component is designed with alignment as a priority,as well as machining and environmental factors like temperature and gravity. Counter rotation may be possible on machines retrofitted with a second rotating group, but will often need to undergo an alignment improvement process which creates additional challenges. Equipment designed with this purpose will have the right combination of benefits to make concentricity tolerances manageable for nearly any operator.

On a counter-rotating drilling machine, a good operator interface will provide a full picture of process information, as well as allow control over process parameters, for fine-tuning and process repetition. Manufacturers can optimize their counter rotation application, and proceed into highly accurate and efficient production.

A general starting point for counter rotation is to allow one third of the total speed to come from the workpiece, and two thirds of the speed to come from the tool. This is a typically recommended starting point for counter-rotating drilling with confidence. Operators can adjust for their specific application, and work with industry partners for recommended parameters to meet deep hole drilling goals.

Productivity Considerations

The addition of counter-rotation in a deep hole drilling process gives operators an additional factor to optimize for both specification and production requirements. The ability to hold improved concentricity tolerances with counter-rotation allows feeds to be run at optimal rates, as well as extends tool life. Manufacturers can reliably produce more parts per hour, with fewer tool changes and improved tool consumption.

For applications where concentricity is indeed critical, the productivity benefits are significant, and easily justify the added capability. Counter-rotation consistently produces a more concentric drilled hole, typically with higher surface cutting speeds, offering clear benefits to manufacturers in both accuracy and efficiency.

Manufacturers can increase capability, improve hole tolerances, and optimize productivity, ultimately cutting costs and providing a competitive manufacturing advantage. With the right resources, drilling deep holes with extreme concentricity is economical, repeatable, and commercially viable.