Dec

IMPROVING BORE QUALITY WITH SKIVING AND ROLLER BURNISHING

- 2025

- Ampersand Milwaukee

Skiving and roller burnishing is one of the most surprisingly productive ways to achieve high-quality bore finishing in OEM production. Even experienced machinists are impressed when they see raw tubing converted into a mirror-like finish in a single pass at extremely high feed rates. This is achieved by combining two operations into a single tool and having the right machine for the job.

The process works by using a set of floating knives on the front of the tool, followed by rollers. The diameter and finish are adjustable on the head to “dial” in the exact sizes, and the finish can be tuned by adjusting the roller pressure relative to the cutting diameter. Cutting fluid floods the tool to clear chips, and hydraulic actuation protects the finished surface as the tool retracts. The process delivers outstanding accuracy, surface durability, and repeatability across a wide range of bore sizes and production environments.

ACHIEVABLE RESULTS

ACHIEVABLE RESULTS

"Skiving and roller burnishing combines two operations into a single tool."

APPLICATION AND PRODUCTION FLEXIBILITY

UNISIG MACHINES BUILT FOR THE PROCESS

APPLICATION RANGE AND PRODUCTION FLEXIBILITY

UNISIG MACHINES BUILT FOR THE PROCESS

FREQUENTLY ASKED QUESTIONS

Skiving and roller burnishing combine cutting and finishing in a single tool, allowing raw tubing to be converted into a mirror-like finish in one pass. High feed rates, adjustable tool settings, and efficient chip evacuation allow the process to achieve speeds and quality levels that exceed conventional drilling, milling, or turning.

The process supports a wide range of bore diameters from 30 to 500 mm (1.18 to 20 inches) and depths beyond 6 meters (20 feet). UNISIG has applied skiving and roller burnishing to depths exceeding 13 meters (43 feet) in demanding applications.

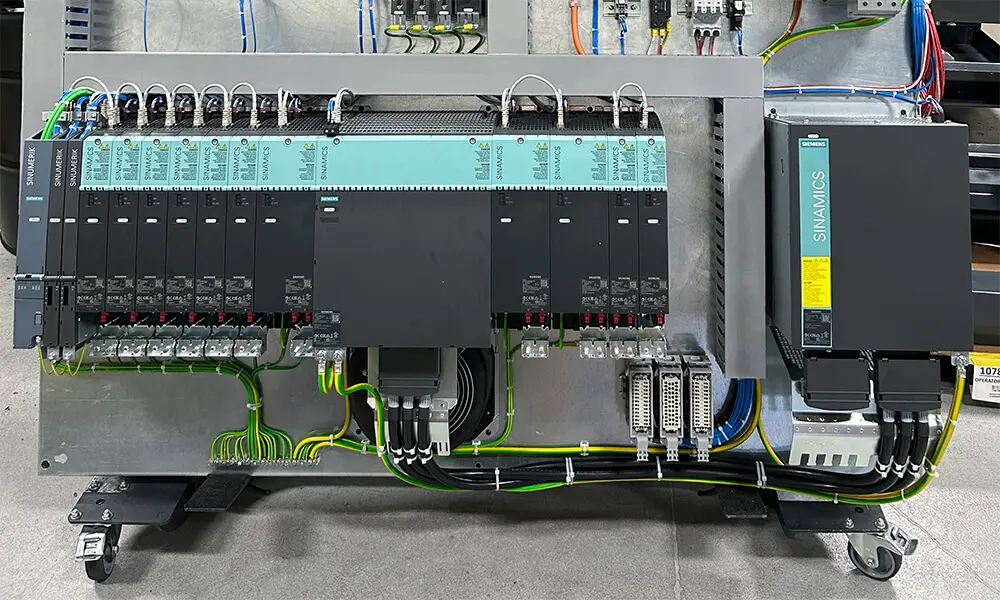

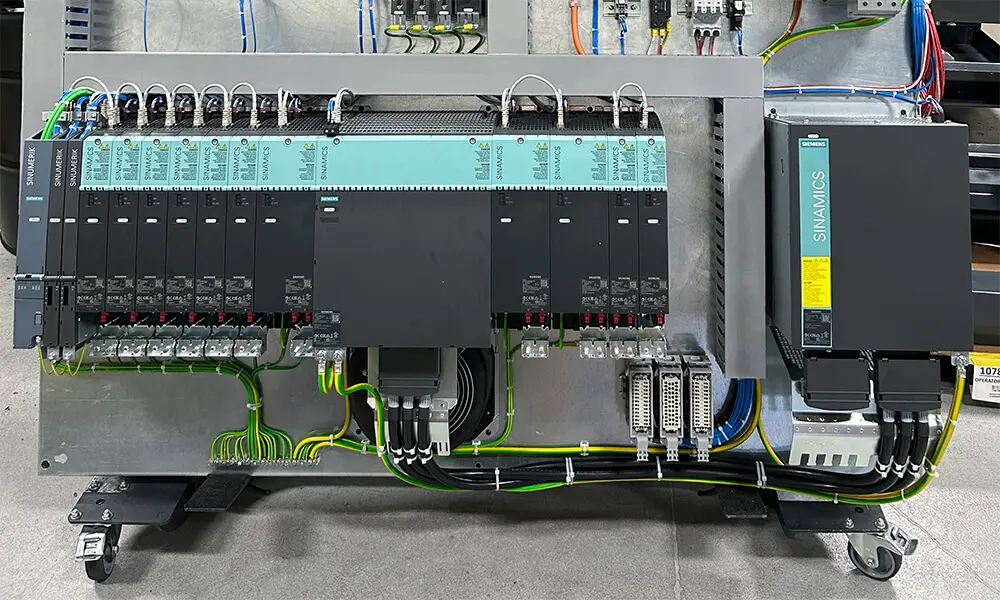

UNISIG S-Series machines are purpose built for tube production and designed specifically around the skiving and roller burnishing process. B-Series BTA deep hole drilling machines can also integrate this capability, enabling manufacturers to produce both the starting bore and the final high quality finish on one platform.

Nov

ENERGY EFFICIENCY AT UNISIG

- 2025

- Ampersand Milwaukee

Energy efficiency is one area where everyone can agree. It is beneficial for the planet and for profits. A small gundrilling machine may have less than 20 horsepower, while a large BTA drilling machine can exceed 200 horsepower. Regardless of size, every kilowatt-hour of electricity matters. UNISIG designs machines with efficiency in mind because we believe that is how well-planned, modern machines should be built—through thoughtful engineering and design choices that reduce energy consumption and improve performance.

DESIGNING FOR MECHANICAL EFFICIENCY

DESIGNING FOR MECHANICAL EFFICIENCY

"Mechanically efficient designs run cooler, hold tighter tolerances, and last longer."

SMART SYSTEMS THAT CONSERVE ENERGY

COMMITMENT BUILT INTO EVERY MACHINE

SMART SYSTEMS THAT CONSERVE ENERGY

COMMITMENT BUILT INTO EVERY MACHINE

FREQUENTLY ASKED QUESTIONS

Because efficiency impacts both performance and sustainability. Well-designed, efficient machines reduce waste, lower operating costs, and improve reliability.

They recover kinetic energy and, in many cases, return high-quality power to the grid.

Yes, positively. Efficient designs reduce heat, maintain precision, and extend component life, leading to improved accuracy and uptime.

Nov

WHEN IS TREPANNING THE RIGHT CHOICE?

- 2025

- Ampersand Milwaukee

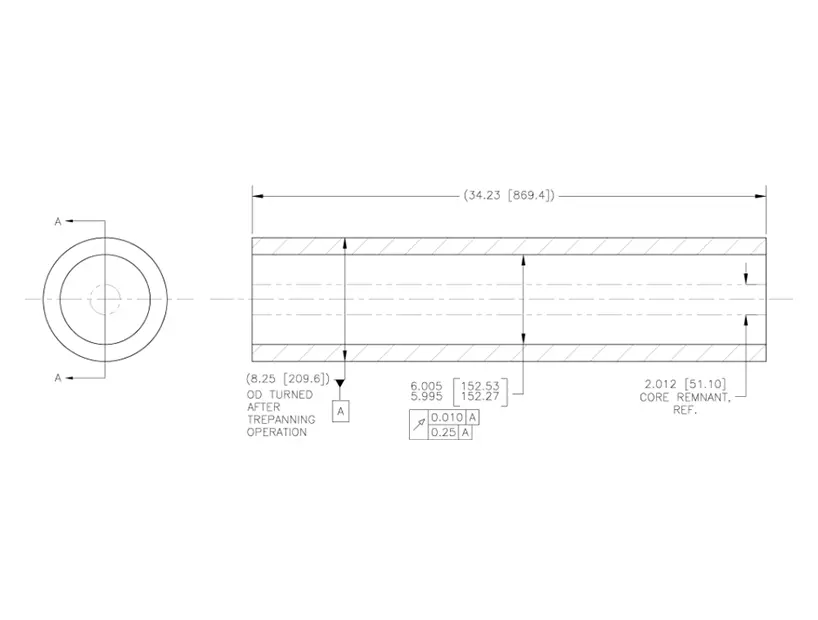

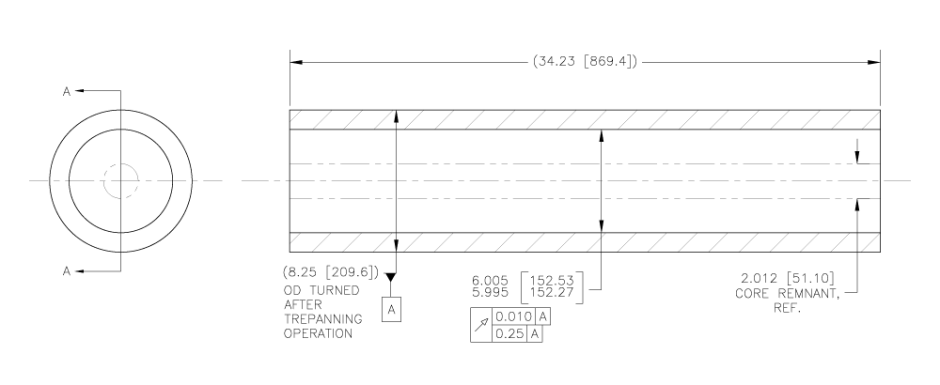

Trepanning is a process that creates a hole in a workpiece by machining only the outer area of the hole, leaving an unmachined core in the center. In contrast, a BTA drill creates the same hole by turning all of the material into chips, leaving no core behind. This provides manufacturers with two distinct ways to create a hole from solid material.

BTA drilling is simple in concept: set up the machine, drill the hole, remove the workpiece, and empty the chip hopper when it’s full. Many manufacturers choose this process for its straightforward operation and the convenience of chip recycling. Trepanning isn’t necessarily more difficult, but it requires more operator involvement. When the hole is complete, the retained core must be removed from the tool between cycles.

Trepanning and BTA solid drilling share the same coolant delivery and chip evacuation systems. Coolant is introduced around the outside of the tool, and chips are exhausted through the drill tube. In BTA drilling, coolant passes freely through the tube, carrying chips to the conveyor. In trepanning, however, chips taken by the coolant must pass by the workpiece core inside the tube. The bore quality between the two methods can be similar, but it depends on the tool design. Trepanning tools with a sufficient cutting width to engage guide pads can achieve diameter tolerances similar to solid drilling. Tools designed for the narrowest width of cut (leaving the largest core) generally produce lower bore quality. For very deep holes, a counter-rotating tool and workpiece are often used. Because the trepanning core rotates with the workpiece, it can create challenges related to vibration or unexpected loading. Once these differences are understood, the key question becomes: When is trepanning the right choice?

ADVANTAGES OF TREPANNING

ADVANTAGES OF TREPANNING

“Trepanning is not just an alternative to BTA drilling—it’s a strategic choice when core recovery, power efficiency, or tooling economy align with production goals.”

LIMITATIONS AND CONSIDERATIONS

EQUIPMENT FOR TREPANNING

LIMITATIONS AND CONSIDERATIONS

EQUIPMENT FOR TREPANNING

FREQUENTLY ASKED QUESTIONS

Trepanning is ideal when core recovery or reduced tooling cost is valuable, or when material properties must be preserved for testing or reuse.

It’s possible, but challenging. Specialized core-breaking or cropping tools are required to separate the core, which adds time and complexity.

Machines must be powerful, and designed for core handling. UNISIG B-Series machines can perform both trepanning and BTA drilling, offering flexibility for different applications.

Nov

PAINT BOOTH INVESTMENT: PRECISION PAINTING FOR UNISIG MACHINES

- 2025

- Ampersand Milwaukee

UNISIG machines are designed to run for 20 years or more in production. While operating, the machines are exposed to factory conditions that are not ideal for precision machinery. Cutting fluid—whether straight oil or water-soluble—contains extreme pressure (EP) additives that improve tool performance but can degrade or damage seals and paint on the machines over time. We want our machines to look good while they age. Part of our strategy for this is to use a two-component polyurethane enamel to paint our base castings, structural frames, machine enclosures, or any fabricated metal parts in our machines. Recently, we targeted our painting department for investment to keep up with our growing company and expanding product line. Our goals for investment were clear:

- Improve the shop environment in the painting area

- Improve the quality of the finished product

- Increase the dimension of parts we could paint

- Reduce the amount of paint used and wasted

- Increase the productivity in painting

- Increase the throughput in the paint department

Manufacturing engineers researched the technology available, and as in most cases in manufacturing, we were even more excited about the project after learning what was possible.

DIMENSIONS AND INTERIOR

“It’s an investment in long-term quality, efficiency, and the appearance of every UNISIG machine that leaves our facility.”

DIMENSIONS AND INTERIOR

“It’s an investment in long-term quality, efficiency, and the appearance of every UNISIG machine that leaves our facility.”

AIR HANDLING AND PAINT MIXING

TRAINING, MAINTENANCE, AND CONTINUOUS IMPROVEMENT

AIR HANDLING AND PAINT MIXING

TRAINING, MAINTENANCE, AND CONTINUOUS IMPROVEMENT

FREQUENTLY ASKED QUESTIONS

UNISIG machines are built to perform for decades in production environments, often exposed to cutting fluids and other challenging factory conditions. The investment into advanced paint technology helps protect critical components, maintain a professional appearance, and ensure long-term durability.

The upgraded booth allows UNISIG to paint larger machine components with greater precision and efficiency. It features improved lighting, controlled air handling, and a crane access system for handling large parts—resulting in higher quality finishes and increased throughput.

The automatic mixing system precisely controls the two components of the polyurethane enamel at the spray gun. This ensures a perfect mix every time, reduces paint waste, and gives painters better control over color selection and solvent use—all contributing to consistent, high-quality finishes.

Nov

MANUFACTURING INNOVATION DRIVES ENGINEERING INNOVATION

- 2025

- Ampersand Milwaukee

Every company that builds advanced technology products is chasing engineering innovation, looking for clever and practical designs that separate them from the competition. Precision machine tools and automation have evolved to incredible levels because of constant competitive pressure, but that same pressure can leave design engineers searching for fresh inspiration.

Where does true design innovation come from? While inspiration can occasionally strike out of nowhere, relying on those rare moments is not a sustainable strategy when your profession demands a consistent output of high-quality designs. One of the most reliable and enduring sources of engineering innovation comes from a strong, ongoing connection to manufacturing.

INNOVATION MEETS REALITY

INNOVATION MEETS REALITY

“We have an endless source of engineering innovation that comes directly from innovations in manufacturing.”

MANUFACTURING EXPANDS POSSIBILITIES

KEEPING ENGINEERING AND MANUFACTURING TOGETHER

MANUFACTURING EXPANDS POSSIBILITIES

KEEPING ENGINEERING AND MANUFACTURING TOGETHER

FREQUENTLY ASKED QUESTIONS

Manufacturing advancements expand what is physically possible to build. When engineers stay connected to the shop floor, they gain real-world insights about materials, processes, and tolerances that influence smarter, more efficient designs.

Close collaboration ensures that designs are practical, efficient to produce, and optimized for quality and performance. When both teams operate in the same facility, feedback flows naturally, leading to faster innovation and fewer design challenges.

UNISIG builds its critical components in-house, investing in advanced machinery, technology, and training. By keeping manufacturing and engineering under one roof, the company maintains full control over production and continuously drives innovation in both areas.